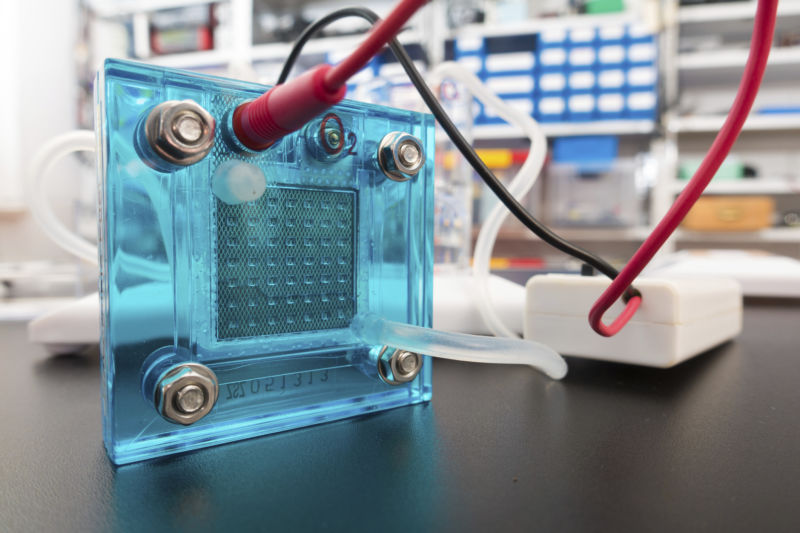

http://www.theregister.co.uk/2018/0...battery_ambition_see_a_10x_increase_in_power/Russian boffins at the Moscow Institute of Physics (MIPT) have emitted a prototype nuclear battery packing 3,300 milliwatt hours of energy per gram.

The paper, published in Diamond and Related Materials, describes a betavoltaic battery powered by the beta decay of the nickel-63 isotope giving 10 times the power of conventional commercial cells.

Betavoltaics themselves are nothing new, using semiconductors to convert the energy of beta decay into electricity, and found use briefly in the 1970s in pacemakers due to their longevity. However, cheaper chemical batteries with their higher power densities (if shorter lifespans) won the day.

The public perception and fear of all things radioactive at the time did the concept no favours either.

The team at MIPT have come up with a way to deal with the power density problem by using nickel-63 as the power source (and a known quantity thanks to earlier research in both Russia and Bristol) and Schottky barrier-based diamond electrodes for the energy conversion in a novel configuration.

200 of the diamond converters were interlaid with nickel-63 and stable nickel foil layers, with the power generated dependant on the thickness of the foil.

If the foil is too thick, the emitted electrons cannot escape due to self-absorption. However, make the foil too thin and the number of atoms undergoing decay over time is reduced. Using simulation tools, the team calculated that the sweet spot required the nickel-63 foil be 2 micrometres thick with the Schottky barrier diamond converter at 10 micrometres.

Manufacturing the converters presented its own particular challenges, with the team developing a way of growing diamond plates on a diamond substrate by first creating a damaged layer in the substrate through ion implantation, growing boron-doped diamond film on top and then using annealing to allow the recovery of the top layer.

Once the damaged layer was separated by electrochemical etching, the converter was fitted with ohmic and Schottky contacts.

Boffins used the process to create 200 converters from 20 substrates, stacking the things with the nickel-63 foil to create a battery with an open-circuit voltage of 1.02 V and a current of 1.27 μA.

With a power density per cubic centimetre of 10 microwatts, a more economical manufacturing process and nickel-63 having a half life of 100 years, the researchers see potential for the battery to be used as a power source that does not need to be replaced in medical devices such as pacemakers.

The team also see opportunities for use in powering spacecraft systems such as memory chips with their own power supplies.

Going forwards, the boffins reckon that enriching the nickel-63 would proportionately increase the power, as would switching from a Schottky barrier diode to a diamond P-I-N structure.

With a shortage of nickel-63 production in Russia until at least the mid 2020s the team are also considering the possibility of using the diamond convertor technology with alternative isotypes such as carbon-14, which has a half life of 5,700 years.

The team in Bristol published research into using the carbon-14 isotype in 2016, incorporating the nuclear waste into a man-made diamond to ensure no unpleasant short-range radiation can escape.

Incorporating the Russian technology to boost power output would see more applications for the technology than just long-term low-power scenarios.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Energian tuotanto, kenttägeneraattorit ja muut

- Viestiketjun aloittaja ctg

- Aloitus PVM

https://electrek.co/2018/06/29/tesla-pge-giant-1-gwh-powerpack-battery-system/For the past few months, Tesla and CEO Elon Musk have been teasing a giant battery project that would dwarf even the company’s 129 MWh Powerpack project in Australia.

Today, we learn that Tesla is working with PG&E on a massive battery system with a capacity of “up to 1.1 GWh” in California.

Pacific Gas and Electric Company (PG&E), one of the largest electric energy companies in the United States covering nearly 16 million people in Northern and Central California, submitted 4 new energy storage projects to the California Public Utilities Commission (CPUC) for approval today.

Three are third-party owned projects to be connected to PG&E’s grid, but the fourth one is “a proposed utility-owned 182.5 MW lithium-ion battery energy storage system (BESS) located within PG&E’s Moss Landing substation.”

Tesla would be providing the battery packs for the giant project, which would be able to output 182.5 MW of power for 4 hours, which represents 730 MWh of energy capacity or over 3,000 Tesla Powerpack 2s.

PG&E also has the option to increase the capacity to 6 hours for a total of 1.1 GWh.

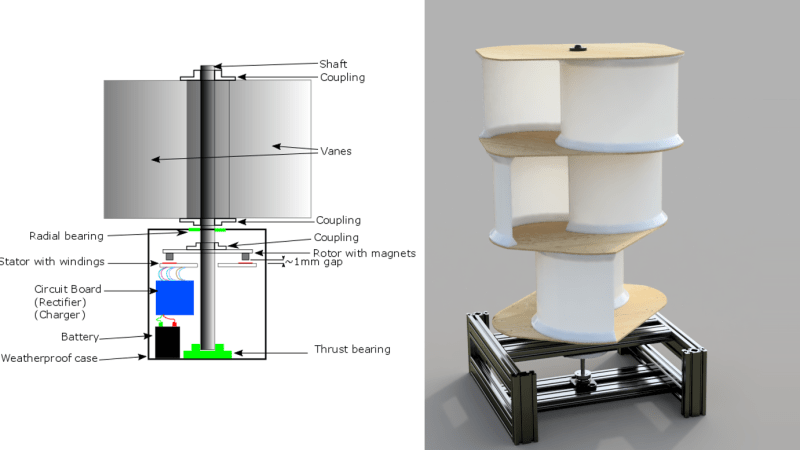

https://hackaday.com/2018/08/14/diy-wind-turbine-for-where-the-sun-doesnt-shine/There are plenty of places outside where you may like to have a project requiring electricity that may not get enough sun for solar power to be viable. Perhaps wind power could be used instead? [Greg] has a project to create a platform for using a small wind turbine to generate the power for your projects.

The wind turbine that [Greg] designing is a Savonius-style wind turbine that would put out between 5 and 12 volts. In a Savonius turbine, blades are mounted on a vertical axis allowing for a smaller, less complicated build than traditional horizontal axis wind turbines. The design is named for its inventor, Finnish engineer Sigurd Johannes Savonius.

After doing some research, the design will have a 2:1 height to blade ratio and use three pairs of overlapping curved blades stacked on top of each other, each pair offset by 120 degrees. This design, [Greg] figures, will come within a few percentage points of the efficiency of more exotic blade shapes while making the windmill easy to design and implement. Being half cylinders, the blades can easily be made from existing objects cut in half – pop cans, for example, but there has been some designing the blades in Fusion 360 for 3D printing. The stator board has been designed and the initial prototypes of it and the rotor have arrived, so the testing can now commence.

Once the design is finalized and the prototype working, it’d be interesting to see some projects start showing up using wind power instead of solar power. Take a look at this design for a vertical wind turbine, and this design for a simple, straightforward turbine.

Suomalainen keksintö. Insinörtti voi helposti tehdä tämän kentällä 3d printterin avulla.

A concrete "battery" could be the future of energy storage. Energy Vault, a Swiss startup, has created a way to store electricity in concrete blocks. The technology helps use solar power when sun doesn't shine and wind power when the wind doesn't blow. It's a low-tech alternative to lithium-ion batteries.

There’s been a lot of progress in renewable energy with solar and wind power, but renewable energy storage remains a challenge. Energy Vault’s idea is similar to hydroelectric power, but instead of using water and dams, it uses concrete blocks and cranes. The low-cost, low-tech solution is proof that some of the answers to our energy-storage problems may be hiding in plain sight.

https://theconversation.com/solar-panels-replaced-tarmac-on-a-road-here-are-the-results-103568Unable to benefit from air circulation, its inevitable these panels will heat up more than a rooftop solar panel too. For every 1C over optimum temperature you lose 0.5% of energy efficiency. As a result a significant drop in performance for a solar road, compared to rooftop solar panels, has to be expected.

https://spectrum.ieee.org/energywis...-solarstorage-systems-explodes-in-puerto-ricoIEEE Spectrum: In the wake of Hurricane Maria, have you noticed a shift in people’s attitudes toward solar projects?

Gabriel Rivera: The solar market in Puerto Rico just completely changed after the hurricane. At my business Verdifica, we used to mostly do design and consulting for grid-tied solar installations, with net metering. I would say 95 percent of the projects had no batteries. After the hurricane, 100 percent of the projects we’ve done include batteries, even though it almost doubles project costs.

Our customers lost confidence in solar without batteries, because many people with grid-tied systems didn’t have a way to use their solar panels during the extended outage. Now, everyone has requested to have at least a bit of power backup.

Our systems usually run between [US] $20,000 to $30,000, for 3 to 5 kilowatts of photovoltaic (PV) capacity, with around 10 kilowatt-hours of usable storage. Everybody is going for self-consumption programming, so that they buy as little electricity as possible from the grid. The key is to get PREPA out of your bill.

The only problem is that really few people have money to actually get solar.

Spectrum: Are you still building and donating small solar kits for people with medical needs?

Rivera: We did about 40 to 50 projects across the island, and people still have those in their homes, but we don’t do any more urgent installations right now, because most people have power again. But some family members and neighbors of the patients were like, “I want something like this, too.” So we’re actually manufacturing a product that is low-budget—around $4,000—to run your lights, refrigerator, and so on, and we’re working with two foundations.

Some clients are opting for solar only because they need the power quality. There’s so much intermittency in the grid that it damages their appliances, and they’re tired of having their TV, modem, and refrigerator gone because of brownouts. They have opted to use an off-grid, isolated, and dedicated PV system just for that equipment. They don’t want to rely on the grid any more.

It’s a laboratory here; I’m so busy doing so many different requests. There are a lot of people who live in multilevel buildings who don’t have a way to put solar on the roofs, but they do need some type of backup as well, at least for their refrigerators and lights so they can survive an extended outage. So we’re installing systems with an inverter charger and batteries, just without the solar component.

Spectrum: As PREPA struggled to restore power, Puerto Rico adopted measures to allow more electricity installations and microgrid projects. How did that affect your business?

Rivera: PREPA changed their way of classifying PV projects, allowing us to do the projects first and then ask for permission. Now, for projects that are less than 10-kilowatt PV, it’s fast-tracked. You don’t need an inspection, whereas before you had to do this for every single project. Because of that, a lot of smaller projects are going up.

Solar is so competitive right now that prices have gone down. I can even say that electrical materials are in more stores now than before the hurricane, like conduits, breakers, and distribution equipment. But it’s also very chaotic. It’s regulated, but it’s kind of an open market for anybody to do residential projects.

In my opinion as an engineer, there’s nothing here that I can call a microgrid yet. The word “microgrid” is being abused right now. People just think it’s an island, but a microgrid has other points of interconnectivity. If you have a set of distributed generators, that’s what you have: distributed generators—a microgrid has to share energy. Right now, we have net metering, so we are sharing energy without having to call that a microgrid. But the energy security of an actual microgrid is something else.

Spectrum: What other recent challenges have you experienced with solar installations?

Rivera: The grid’s power quality is still not good. At some installations, we’re having to slightly broaden the voltage and frequency ranges in order for the equipment to recognize the grid service as the grid service, and not classify it as dirty power, as per IEEE 1547 (the standard for interconnection and interoperability of distributed energy resources with associated electric power systems interfaces).

One of the problems with this is that it puts some of the battery-based systems to “off-grid” mode for long times, often leading to unexpected battery drain. System owners find it hard to understand why their solar system is behaving this way, while their neighbors seem to have utility power. And PREPA seems to have way too many problems for us to realistically expect the power quality to be restored to acceptable levels. We’re still working with a lot of uncertainty, and my fear is, how long will this be going on?

Spectrum: What steps are you taking to ensure these installations can withstand future hurricanes?

Rivera: I don’t know if I have seen a single installation that can truly be labeled as “hurricane proof.” The challenge is not only about withstanding the winds, but also about protecting solar panels from loose objects that have become high-speed projectiles. Very small systems, with about six PV modules or less, are easier to simply remove and store during a storm of this kind. The more common residential system sizes here, of about 3 to 10 kW of PV—about 10 to 30 modules—can be unpractical to remove and reinstall.

We’re actually working on a project with local architect Eduardo Rolón Bonilla, in which a 5-kW array of PV modules will be installed on a concrete roof with parapets, in such a way that storm shutters can be integrated to cover and protect against these hazards. The majority of roofs here are flat concrete, and pretty much all the PV systems are fixed-tilt type—no sun tracking. To have some degree of protection against flood damage, good old-fashioned concrete pads are often used to raise floor-mounted batteries or energy storage systems above ground level.

In general, we also like to keep electrical equipment indoors when possible, even when the enclosures are rated for outdoors. Outside temperatures and direct sunlight exposure have shown to be detrimental for this equipment, and rust is also a special reality to consider here. These are some of our basic rules of thumb.

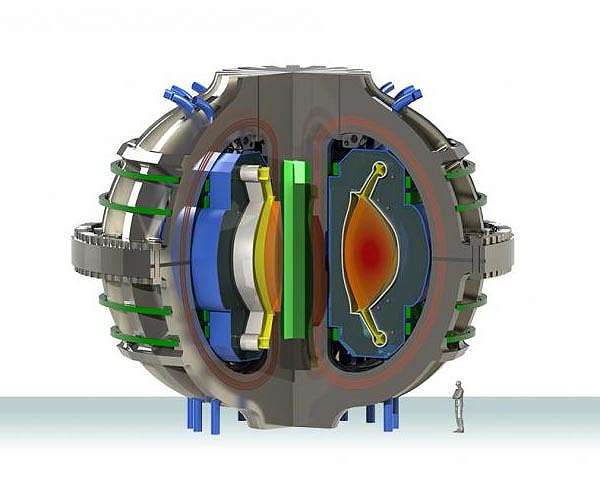

http://www.spacedaily.com/reports/A_new_path_to_solving_a_longstanding_fusion_challenge_999.htmlA class exercise at MIT, aided by industry researchers, has led to an innovative solution to one of the longstanding challenges facing the development of practical fusion power plants: how to get rid of excess heat that would cause structural damage to the plant.

The new solution was made possible by an innovative approach to compact fusion reactors, using high-temperature superconducting magnets. This method formed the basis for a massive new research program launched this year at MIT and the creation of an independent startup company to develop the concept. The new design, unlike that of typical fusion plants, would make it possible to open the device's internal chamber and replace critical components; this capability is essential for the newly proposed heat-draining mechanism.

The new approach is detailed in a paper in the journal Fusion Engineering and Design, authored by Adam Kuang, a graduate student from that class, along with 14 other MIT students, engineers from Mitsubishi Electric Research Laboratories and Commonwealth Fusion Systems, and Professor Dennis Whyte, director of MIT's Plasma Science and Fusion Center, who taught the class.

In essence, Whyte explains, the shedding of heat from inside a fusion plant can be compared to the exhaust system in a car. In the new design, the "exhaust pipe" is much longer and wider than is possible in any of today's fusion designs, making it much more effective at shedding the unwanted heat. But the engineering needed to make that possible required a great deal of complex analysis and the evaluation of many dozens of possible design alternatives.

http://dx.doi.org/10.1016/j.fusengdes.2018.09.007

https://pubs.acs.org/doi/10.1021/acsaem.8b00885The ability to 3D print lithium ion batteries (LIBs) in an arbitrary geometry would not only allow the battery form factor to be customized to fit a given product design but also facilitate the use of the battery as a structural component. A major hurdle to achieving this goal is the low ionic conductivity of the polymers used for 3D printing. This article reports the development of anode, cathode, and separator materials that enable 3D printing of complete lithium ion batteries with low cost and widely available fused filament fabrication (FFF) 3D printers. Poly(lactic acid) (PLA) was infused with a mixture of ethyl methyl carbonate, propylene carbonate, and LiClO4 to obtain an ionic conductivity of 0.085 mS cm–1, a value comparable to that of polymer and hybrid electrolytes. Different electrically conductive (Super P, graphene, multiwall carbon nanotubes) and active (lithium titanate, lithium manganese oxide) materials were blended into PLA to determine the relationships among filler loading, conductivity, charge storage capacity, and printability. Up to 30 vol % of solids could be mixed into PLA without degrading its printability, and an 80:20 ratio of conductive to active material maximized the charge storage capacity. The highest capacity was obtained with lithium titanate and graphene nanoplatelets in the anode, and lithium manganese oxide and multiwall carbon nanotubes in the cathode. We demonstrate the use of these novel materials in a fully 3D printed coin cell, as well as 3D printed wearable electronic devices with integrated batteries.

Jos 3d printatut akut tulevat todellisuuteen, huoltohenkilöstön elämä kentällä voi periaatteessa helpottua. Tosin 3d printattu paristo vaatii jonkinlaisen teknologia millä sitä ladata, mutta onpa sentään mahdollisuus tehdä akkuja jotka eivät ole tavallisia. Scifikirjailia pääni tuottaa mielikuvia missä exoskeletonin akut tulevat osaksi henkilökohtaista panssaria. Ehkä todellisuus on että tuollaiset asiat tapahtuvat vuosisadan loppupäässä, tämän teknologia hautautuessa unholaan.

https://arstechnica.com/science/201...ld-up-efficiency-of-concentrated-solar-power/With the price of photovoltaics having plunged dramatically, solar is likely to become a major contributor to the electrical generating mix in many countries. But the intermittent nature of photovoltaics could put a limit on how much they contribute to future grids or force us to develop massive storage capabilities.

But photovoltaics aren't the only solar technology out there. Concentrated solar power uses mirrors to focus the Sun's light, providing heat that can be used to drive turbines. Advances in heat storage mean that the technology can now generate power around the clock, essentially integrating storage into the process of producing energy. Unfortunately, the price of concentrated solar hasn't budged much, and photovoltaics have left it in the dust. But some materials scientists may have figured out a way to boost concentrated solar's efficiency considerably, clawing back some of photovoltaics' advantage.

En usko että meillä on koskaan mahdollisuus luoda näitä aurinkovoimaloita. Mutta hyvä että kehitys jatkuu niiden kannalla.

https://spectrum.ieee.org/energywise/energy/renewables/alphabets-moonshot-wind-kites-to-fly-offshoreRenewable energy technologies seem to fill every nook and cranny of the earth. Turbines generate power on the seafloor and off coastlines. Solar panels carpet desolate deserts and abandoned wastelands. Volcanic aquifers, mountain streams, and urban sewage systems all help to produce electricity. For Makani, an airborne wind energy company, the next place to tap is roughly 300 meters in the air.

The California startup recently spun out of X—Alphabet’s experimental technology lab, or “moon shot factory”—to become an independent business within Google’s parent company. Makani is also partnering with Royal Dutch Shell in a bid to launch the startup’s high-flying kites where they haven’t flown before: offshore.

Starting this year, Makani will begin testing a floating system for one of its kites at the Metcentre, an offshore wind testing facility in southwest Norway. The kite will be tethered to a small spar buoy, which itself will be moored with a synthetic line and a gravity anchor. The goal is to operate where today’s floating wind turbines can’t go, either because it’s too challenging or cost-prohibitive to build supportive platforms.

“Two-thirds of coastal waters globally are too deep for today’s wind technology to economically access these resources. This is where we think Makani can help," Fort Felker, the CEO of Makani, said in a blog post published 12 February announcing the partnership. (An X representative said Makani and X employees were unavailable for interviews.)

Makani is one of a few startups seeking to harness the higher-speed, more consistent winds that blow at higher altitudes than conventional turbines can reach. Before joining X in 2013, Makani garnered tens of millions of dollars in support from Google’s philanthropic arm and the Advanced Research Projects Agency-Energy at the U.S. Department of Energy. The startup has since scaled its 20-kilowatt proof-of-concept kite into a 600-kilowatt commercial prototype, which engineers are testing at a site in Parker Ranch, Hawaii.

http://www.spacedaily.com/reports/N..._material_offers_strength_resilience_999.htmlA new tungsten-based alloy developed at Los Alamos National Laboratory can withstand unprecedented amounts of radiation without damage. Essential for extreme irradiation environments such as the interiors of magnetic fusion reactors, previously explored materials have thus far been hobbled by weakness against fracture, but this new alloy seems to defeat that problem.

"This material showed outstanding radiation resistance when compared to pure nanocrystalline tungsten materials and other conventional alloys," said Osman El Atwani, the lead author of the paper and the principal investigator of the "Radiation Effects and Plasma Material Interactions in Tungsten Based Materials" project at Los Alamos.

"Our investigations of the material mechanical properties under different stress states and response of the material under plasma exposure are ongoing."

"It seems that we have developed a material with unprecedented radiation resistance," said principal investigator Enrique Martinez Saez, a coauthor of the paper at Los Alamos.

"We have never seen before a material that can withstand the level of radiation damage that we have observed for this high-entropy [four or more principal elements] alloy. It seems to retain outstanding mechanical properties after irradiation, as opposed to traditional counterparts, in which the mechanical properties degrade easily under irradiation."

Arun Devaraj, a materials scientist and project collaborator at Pacific Northwest National Laboratory, noted, "Atom probe tomography revealed an interesting atomic level layering of different elements in these alloys, which then changed to nanoclusters when subjected to radiation, helping us to better understand why this unique alloy is highly radiation tolerant."

The material, created as a thin film, is a quaternary nanocrystalline tungsten-tantalum-vanadium-chromium alloy that has been characterized under extreme thermal conditions and after irradiation.

"We haven't yet tested it in high-corrosion environments," Martinez Saez said, "but I anticipate it should perform well there also. And if it is ductile, as expected, it could also be used as turbine material since it is a refractory, high-melting-point material."

Described this week in a paper in Science Advances, the project was a multi-institutional effort, involving researchers and facilities of Los Alamos National Laboratory, Argonne National Laboratory, Pacific Northwest National Laboratory, Warsaw University of Technology, Poland, and the United Kingdom Atomic Energy Authority.

https://arstechnica.com/science/201...an-run-efficiently-in-reverse-storing-energy/Lithium batteries can readily smooth out short-term hiccups in the supply of intermittent renewable energy. But they're not ideal for long-term storage, since they'll slowly discharge. They also aren't great for large quantities of energy—to store more, you keep having to buy more battery. Because of these issues, there has been research into a number of technologies that scale better, like flow batteries and renewable fuel production. But these pose their own challenges, both chemical and economic.

But researchers are now reporting a possible solution to some of these problems: a fuel cell that can be run efficiently in both directions, either using hydrogen or methane to produce electricity or using electricity to produce these fuels. Their measurements suggest that, after doing a complete cycle, they get out 75 percent of the electricity they put in to start with.

https://thinkprogress.org/replacing-coal-plants-renewables-cost-trump-40a3ff82c2fd/It would be more expensive to keep the majority of U.S. coal plants open than to replace them with new wind and solar power alternatives, according to new findings published Monday.

Authored by the environmental firm Energy Innovation in partnership with the grid analysis company Vibrant Clean Energy, the research finds that replacing 74 percent of coal plants nationally with wind and solar power would immediately reduce power costs, with wind power in particular at times cutting the cost almost in half. By 2025, the analysis indicates, around 86 percent of coal plants could similarly be at risk of cheaper replacement by renewables.

“We’ve been closely following the cost of wind and solar in the U.S. and globally, and the costs have come down so far that we’re now seeing unprecedented low [costs] for wind and solar,” said Mike O’Boyle, Energy Innovation’s electricity policy director, on a call with reporters.

That trend has opened up an opportunity for a dramatic shift, the groups argue, one that could see coal largely replaced in many areas by energy sources that are better for both human health and the environment.

https://spectrum.ieee.org/energy/fo...t-subsea-power-grids-for-underwater-factoriesSlowly but surely, oil- and gas-drilling technology is migrating from floating platforms to the seafloor. Pumps moved down there decades ago. More recently, compressors (which boost pressure in a well to keep gas flowing) and separators (which isolate oil from water and silt) have relocated to the murky depths.

Putting this equipment closer to wells makes them more productive and energy efficient. Some oil and gas companies even aspire to build subsea factories that extract and process oil and natural gas directly on the seafloor. These factories would be safe from hazards such as icebergs and hurricanes. They would be controlled remotely, reducing labor costs. Eventually, some believe, offshore platforms could be phased out entirely.

However, all of this sunken gear requires electricity. Today, operators typically string power lines from power plants or diesel generators aboard nearby oil rigs to every piece of subsea equipment they install. That works for a few machines, but it’s impractical to string dozens of umbilicals, as they’re known, to the ocean floor.

Industry suppliers ABB and Siemens are now putting the finishing touches on competing versions of the world’s first subsea power-distribution stations. Once installed, these stations would connect via a single line to a “topside” (maritime parlance for above water) generator, wind turbine, or power plant, and redistribute electricity to underwater equipment. “Our technology is an enabling technology for the subsea factory,” says Bjørn Rasch, head of subsea power for Siemens.

Tätä on kuulemma testattu Suomessa

https://thinkprogress.org/europe-wi...ered-in-two-decades-experts-say-8db3e7190bb7/The myth that a very high level of renewables can’t be integrated into the electric grid is being demolished by the clean tech and battery storage revolution.

“By 2040, renewables make up 90% of the electricity mix in Europe, with wind and solar accounting for 80%,” predict the experts at Bloomberg New Energy Finance (BNEF) in their annual energy outlook released this week.

“Cheap renewable energy and batteries fundamentally reshape the electricity system,” explains BNEF. Since 2010, wind power globally has dropped 49% in cost. Both solar and battery prices have plummeted 85%.

Mili

Eversti

Ihmettelen puukaasun käyttämättömyyttä kriisinajan skenaarioissa. Luulisi että nestemäisillä polttoaineilla olisi parempaakin tekemistä kuin sähkön tekeminen.

Nykytekniikalla, materiaaleilla(kunnon laastit, rosteri, haponkestävä, lasikuitu suodattimena entisaikojen orgaanisten sijaan) ja virtaustekniikan simulointiohjelmilla uskoisin olevan suhthelppoa tehdä kaasutusyksikkö jonka voisi liittää suoraan moottorin ilmanottoon. Siinä olisi siis kiinteästi kaasutusyksikön jatkona letku jonka päässä olisi "kaasutin" eli laite joka sekoittaisi valmiiksi kaasun ja ilman sopivassa suhteessa. Bensiinikäyttöisiä varten voisi olla pieni kaasutin tai ruisku jolla voisi antaa sytytysapua pienellä bensamäärällä. Dieselillä taidetaan ruiskutuspumppu jättää ruiskuttamaan tyhjäkäyntimäärää sylinteriin.

Pilkkeitten teon voisi automatisoida tai sitten siirtyä pellettien käyttöön. Ne kaasuuntuvat hieman hankalammin kuin puu, vaatinee kehittämistä ja kokeita.

https://www.nrel.gov/docs/legosti/old/3022.pdf

http://www.driveonwood.com/library/fema-gasifier/

https://www.build-a-gasifier.com/gasifier-plans/

Maininta, 1,4kg puuta vastaa 1kWh sähköä. Muistaakseni puussa on 4kWh energiaa per kilo. Aika huono hyötysuhde siis, osa hukkaenergiasta voidaan käyttää lämmitykseen?

https://www.flux-i.com/

Hiiltä voi myös käyttää, helpompi kuin puu, koska kaasun puhdistus paljon helpompaa. Terva puuttuu, vain tuhka tarvitsee suodattaa. Voi käyttää pienkoneissa mm. moottorisahassa. Olen nähnyt jossain kuvan laitteesta joka on tehty sammuttimesta. Pohja pois, ylösalaisin, säiliön eristys, kaasuletku reiästä joka jää kun poistetaan kahva, ja letku klapisirkkeliin. Ei paljoa yksinkertaisempi voi olla, sopiva SHTF-tilanteisiin?

https://www.instructables.com/id/Charcoal-Fire-Powered-Generator/

https://wiki.opensourceecology.org/wiki/Charcoal_Gasifier

Hiukan isomman mittakaavan tekniikkaa:

https://www.valmet.com/energyproduction/gasification/

PS: Usein kaasua on pesty vedellä. Mietin että pitääkö siihen käyttää sähköpumppua, mutta autoon asennetuissa riittäisi joku varren päässä oleva massa joka heiluttaa kalvopumppua kun täristää tien kuopissa

Nykytekniikalla, materiaaleilla(kunnon laastit, rosteri, haponkestävä, lasikuitu suodattimena entisaikojen orgaanisten sijaan) ja virtaustekniikan simulointiohjelmilla uskoisin olevan suhthelppoa tehdä kaasutusyksikkö jonka voisi liittää suoraan moottorin ilmanottoon. Siinä olisi siis kiinteästi kaasutusyksikön jatkona letku jonka päässä olisi "kaasutin" eli laite joka sekoittaisi valmiiksi kaasun ja ilman sopivassa suhteessa. Bensiinikäyttöisiä varten voisi olla pieni kaasutin tai ruisku jolla voisi antaa sytytysapua pienellä bensamäärällä. Dieselillä taidetaan ruiskutuspumppu jättää ruiskuttamaan tyhjäkäyntimäärää sylinteriin.

Pilkkeitten teon voisi automatisoida tai sitten siirtyä pellettien käyttöön. Ne kaasuuntuvat hieman hankalammin kuin puu, vaatinee kehittämistä ja kokeita.

https://www.nrel.gov/docs/legosti/old/3022.pdf

http://www.driveonwood.com/library/fema-gasifier/

https://www.build-a-gasifier.com/gasifier-plans/

Maininta, 1,4kg puuta vastaa 1kWh sähköä. Muistaakseni puussa on 4kWh energiaa per kilo. Aika huono hyötysuhde siis, osa hukkaenergiasta voidaan käyttää lämmitykseen?

https://www.flux-i.com/

Hiiltä voi myös käyttää, helpompi kuin puu, koska kaasun puhdistus paljon helpompaa. Terva puuttuu, vain tuhka tarvitsee suodattaa. Voi käyttää pienkoneissa mm. moottorisahassa. Olen nähnyt jossain kuvan laitteesta joka on tehty sammuttimesta. Pohja pois, ylösalaisin, säiliön eristys, kaasuletku reiästä joka jää kun poistetaan kahva, ja letku klapisirkkeliin. Ei paljoa yksinkertaisempi voi olla, sopiva SHTF-tilanteisiin?

https://www.instructables.com/id/Charcoal-Fire-Powered-Generator/

https://wiki.opensourceecology.org/wiki/Charcoal_Gasifier

Hiukan isomman mittakaavan tekniikkaa:

https://www.valmet.com/energyproduction/gasification/

PS: Usein kaasua on pesty vedellä. Mietin että pitääkö siihen käyttää sähköpumppua, mutta autoon asennetuissa riittäisi joku varren päässä oleva massa joka heiluttaa kalvopumppua kun täristää tien kuopissa

http://www.spacedaily.com/reports/Supercapacitors_turbocharged_by_laxatives_999.htmlAn international team of scientists, including a professor of chemistry from the University of Bristol, has worked out a way to improve energy storage devices called supercapacitors, by designing a new class of detergents chemically related to laxatives.

Their paper, published in the journal Nature Materials, explains why these detergents, called ionic liquids, are better electrolytes than current materials and can improve supercapacitors.

Currently, aqueous and organic electrolytes are used, but more recently, researchers and manufacturers have been testing ionic liquids instead to boost performance.

Although ionic liquids are salts, at room temperature they are surprisingly not crystalline solids - as their name suggests they are in fact liquids.

This gives ionic liquids numerous advantages over conventional electrolytes because they are stable, non-flammable, and often much more environmentally friendly.

To explore the exciting potential offered by ionic liquids for emerging electrochemical technologies the authors designed a new set of highly efficient detergent-like ionic liquid electrolytes and explained how they work at electrode surfaces.

Understanding how they operate will help design even more efficient devices for storing electrical energy.

Professor Julian Eastoe, from the University of Bristol's School of Chemistry, is a co-author of the study. He said: "To make this discovery required a team of scientists with a very diverse skill set, spanning chemical synthesis, advanced structural, microscopy and electrical techniques as well as computational methods.

"This work demonstrates the power of scientific research 'without borders', the groups from different nations contributed their own expertise to make 'the whole greater than the sum of parts'."

Co-author, Xianwen Mao, from the Massachusetts Institute of Technology (MIT), added: "We engineered a new class of ionic liquids that can store energy more efficiently.

"These detergent-like ionic liquids can self-assemble into sandwich-like bilayer structures on electrode surfaces. And that is very reason why they give better energy storage performance."

Typically, for electrolytes in contact with a charged electrode, the distribution of ions is dominated by electrostatic Coulombic interactions.

However, this distribution can be controlled by making the ionic liquids soap-like, or amphiphilic, so that the molecules now have separate polar and non-polar domains, exactly like common detergents.

These soap-like electrolytes then spontaneously form bilayer structures on the electrode surfaces, leading to much improved energy storage capabilities. The researchers found that temperature and applied voltage also affect the energy storage performance.

This new class of electrolytes may be suitable for challenging operations, such as oil drilling and space exploration, but they may also pave the way to new and improved supercapacitors in hybrid cars.

These devices are essential components in modern hybrid cars and can outperform batteries in terms of higher power and better efficiency.

This is particularly the case during regenerative braking where mechanical work is turned into electrical energy, which can be stored quickly in supercapacitors ready to be released.

This reduces energy consumption and is much more environmentally friendly. More importantly, using the new electrolytes such as developed in this study, future supercapacitors may even be able to store more energy than batteries, potentially replacing batteries in applications such as electrical vehicles, personal electronics, and grid-level energy storage facilities.

Umkhonto

Ylipäällikkö

Ihmettelen puukaasun käyttämättömyyttä kriisinajan skenaarioissa. Luulisi että nestemäisillä polttoaineilla olisi parempaakin tekemistä kuin sähkön tekeminen.

Nykytekniikalla, materiaaleilla(kunnon laastit, rosteri, haponkestävä, lasikuitu suodattimena entisaikojen orgaanisten sijaan) ja virtaustekniikan simulointiohjelmilla uskoisin olevan suhthelppoa tehdä kaasutusyksikkö jonka voisi liittää suoraan moottorin ilmanottoon. Siinä olisi siis kiinteästi kaasutusyksikön jatkona letku jonka päässä olisi "kaasutin" eli laite joka sekoittaisi valmiiksi kaasun ja ilman sopivassa suhteessa. Bensiinikäyttöisiä varten voisi olla pieni kaasutin tai ruisku jolla voisi antaa sytytysapua pienellä bensamäärällä. Dieselillä taidetaan ruiskutuspumppu jättää ruiskuttamaan tyhjäkäyntimäärää sylinteriin.

Tässä muutama vaihtoehto. Ei tosin auton päälle pultattava, mutta keskittettynä tuotantokonseptina hyödynnettävissä.

https://www.vtt.fi/palvelut/biotalo...et-polttoaineet/biomassan-ja-jätteen-kaasutus

https://www.vtt.fi/medialle/uutiset/biodieselin-tuotantoon-lisää-tehoa-hajautetulla-tuotannolla

https://www.vtt.fi/palvelut/biotalo...opea-pyrolyysi-biomassan-konversio-bioöljyksi

Ihmettelen puukaasun käyttämättömyyttä kriisinajan skenaarioissa. Luulisi että nestemäisillä polttoaineilla olisi parempaakin tekemistä kuin sähkön tekeminen.

Nykytekniikalla, materiaaleilla(kunnon laastit, rosteri, haponkestävä, lasikuitu suodattimena entisaikojen orgaanisten sijaan) ja virtaustekniikan simulointiohjelmilla uskoisin olevan suhthelppoa tehdä kaasutusyksikkö jonka voisi liittää suoraan moottorin ilmanottoon. Siinä olisi siis kiinteästi kaasutusyksikön jatkona letku jonka päässä olisi "kaasutin" eli laite joka sekoittaisi valmiiksi kaasun ja ilman sopivassa suhteessa. Bensiinikäyttöisiä varten voisi olla pieni kaasutin tai ruisku jolla voisi antaa sytytysapua pienellä bensamäärällä. Dieselillä taidetaan ruiskutuspumppu jättää ruiskuttamaan tyhjäkäyntimäärää sylinteriin.

Pilkkeitten teon voisi automatisoida tai sitten siirtyä pellettien käyttöön. Ne kaasuuntuvat hieman hankalammin kuin puu, vaatinee kehittämistä ja kokeita.

https://www.nrel.gov/docs/legosti/old/3022.pdf

http://www.driveonwood.com/library/fema-gasifier/

https://www.build-a-gasifier.com/gasifier-plans/

Maininta, 1,4kg puuta vastaa 1kWh sähköä. Muistaakseni puussa on 4kWh energiaa per kilo. Aika huono hyötysuhde siis, osa hukkaenergiasta voidaan käyttää lämmitykseen?

https://www.flux-i.com/

Hiiltä voi myös käyttää, helpompi kuin puu, koska kaasun puhdistus paljon helpompaa. Terva puuttuu, vain tuhka tarvitsee suodattaa. Voi käyttää pienkoneissa mm. moottorisahassa. Olen nähnyt jossain kuvan laitteesta joka on tehty sammuttimesta. Pohja pois, ylösalaisin, säiliön eristys, kaasuletku reiästä joka jää kun poistetaan kahva, ja letku klapisirkkeliin. Ei paljoa yksinkertaisempi voi olla, sopiva SHTF-tilanteisiin?

https://www.instructables.com/id/Charcoal-Fire-Powered-Generator/

https://wiki.opensourceecology.org/wiki/Charcoal_Gasifier

Hiukan isomman mittakaavan tekniikkaa:

https://www.valmet.com/energyproduction/gasification/

PS: Usein kaasua on pesty vedellä. Mietin että pitääkö siihen käyttää sähköpumppua, mutta autoon asennetuissa riittäisi joku varren päässä oleva massa joka heiluttaa kalvopumppua kun täristää tien kuopissa

Itse lähtisin ajattelemaan ilman sähköä, kaasuletku vesisäiliön pohjalle ja imuletku moottoriin vedenpinnan päälle. Alan miehet näkee periaatteen vesipiipussa. Pyrolyysikattila kotiin olisi mainio kyllä, biomassasta lähtien kaikki kelpaa ja kaasulla pyörii genu, polttolämpö varaajaan ja varaajalla mökki lämpimäksi ja genun sähköllä telkkari tulille.