Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Energian tuotanto, kenttägeneraattorit ja muut

- Viestiketjun aloittaja ctg

- Aloitus PVM

PekkaSavo

Ylipäällikkö

Tilanne jossa on pula ajoneuvojen polttoaineesta ja ulkomailta ei saada juuri mitään. Syynä jokin ulkopuolella tapahtunut häiriö tai konflikti (ei siis välttämättä "Suomi sodassa"). Sähköverkko toimii vajaalla ja sähköautot tyhjinä. Kumpaa silloin kyetään helpommin tuottamaan, biodiesel vaiko biobensa / alkoholi?

http://www.tiede.fi/keskustelu/9567/ketju/biobensiini

jossa joku heittää arvion

"En tiedä Ruotsin lukuja, mutta pariin aikasempaan täällä käytyyn ihan vastaavaan jorinaan kaivoin joitakin lukuja. Siis jos autobensiini korvattaisiin täysin kotimaisella "peltometanolilla", niin sen viljelysalaksi tarvittaisiin noin 1,4 miljoonaa peltohehtaaria. Nykyinen Suomen yhteenlaskettu peltoviljelysala on 1,2 miljoonaa hehtaaria. Eli edes maan kaikki nykyiset pellot eivät riittäisi tarpeellisen etanoli/metanoli määrän tuottamiseen."

Paljonko tarvitaan edes siihen että välttämättömimmät välineet liikkuvat?

http://www.tiede.fi/keskustelu/9567/ketju/biobensiini

jossa joku heittää arvion

"En tiedä Ruotsin lukuja, mutta pariin aikasempaan täällä käytyyn ihan vastaavaan jorinaan kaivoin joitakin lukuja. Siis jos autobensiini korvattaisiin täysin kotimaisella "peltometanolilla", niin sen viljelysalaksi tarvittaisiin noin 1,4 miljoonaa peltohehtaaria. Nykyinen Suomen yhteenlaskettu peltoviljelysala on 1,2 miljoonaa hehtaaria. Eli edes maan kaikki nykyiset pellot eivät riittäisi tarpeellisen etanoli/metanoli määrän tuottamiseen."

Paljonko tarvitaan edes siihen että välttämättömimmät välineet liikkuvat?

Kumpaa silloin kyetään helpommin tuottamaan, biodiesel vaiko biobensa / alkoholi?

Alkoholi meidän tapauksessa. Mutta tekniikka on tuonut myös kyvyn uudelleen jalostaa muovia dieseliksi.

Paljonko tarvitaan edes siihen että välttämättömimmät välineet liikkuvat?

Tämän tiedon voi löytää tilastoista varmuusvarastojen kohdalta.

http://spectrum.ieee.org/tech-talk/...bendable-lithiumion-battery-for-iot-wearablesMost wireless electronic devices look the way they do because of their batteries. Batteries are bulky and rigid components that can’t easily be modified or eliminated. So when product developers design a new device, the battery is often the limiting factor in determining size, shape, and flexibility.

But this year at CES in Las Vegas, Panasonic is showing off a new type of lithium-ion battery that could change that. The razor-thin silver wafer can be twisted or bent 1,000 times and still maintain 80 percent of its capacity. Panasonic presented three versions of the new battery at CES: Each is slightly smaller than a credit card and bendy enough to fit around a soda can’s contours.

The project has been under way since 2008, but Panasonic just started talking about it in September. Yoriko Yagi, assistant chief of planning in Panasonic’s wearable energy department, said the battery is now ready for mass production, which she expects will begin sometime between April 2018 and March 2019.

Nhhk

Kenraali

Pitää muistaa että myös turpeesta pystytään tuottamaan polttoainetta, ja sitähän meillä riittääSiis jos autobensiini korvattaisiin täysin kotimaisella "peltometanolilla", niin sen viljelysalaksi tarvittaisiin noin 1,4 miljoonaa peltohehtaaria. Nykyinen Suomen yhteenlaskettu peltoviljelysala on 1,2 miljoonaa hehtaaria. Eli edes maan kaikki nykyiset pellot eivät riittäisi tarpeellisen etanoli/metanoli määrän tuottamiseen."

Paljonko tarvitaan edes siihen että välttämättömimmät välineet liikkuvat?

En tiedä, mutta valmiusvarastot riittäisivät varsin pitkään, jos siis vain välttämättömimmät välineet liikkuisivat.

Nurkantakanen

Kapteeni

Biodieseliä sellunvalmistuksen sivutuotteena:

UPM Lappeenrannan tuotantokapasiteetti on 100 000 tonnia biodieseliä vuodessa, mikä 4 % Suomen vuotuisesta dieselin kulutuksesta (2,5 milj. tonnia). Raaka-aineena käytetään mäntyöljyä, jota saadaan sellunvalmistuksen sivutuotteena.

Nesteen Porvoon jalostamon NExBTL kapasiteetti on 170 000 tonnia vuodessa. Melkein mikä tahansa kasviöljy tai eläinrasva kelpaa raaka-aineeksi.

Yhdessä näillä yksiköillä voidaan tuottaa noin 10 % maan dieselin kulutuksesta.

Lisäksi Finnpulp suunnittelee Kuopioon havusellutehdasta, joka tuottaisi sellun ohessa 60 000 tonnia mäntyöljyä vuodessa.

http://www.upmbiopolttoaineet.fi/bi...-lappeenrannan-uusi-laitos/Pages/Default.aspx

https://www.neste.com/fi/fi/puhtaammat-ratkaisut/tuotteet/uusiutuvat-polttoaineet

http://www.finnpulp.fi/havusellutehdas-finnpulp.html

https://fi.wikipedia.org/wiki/Biodiesel

UPM Lappeenrannan tuotantokapasiteetti on 100 000 tonnia biodieseliä vuodessa, mikä 4 % Suomen vuotuisesta dieselin kulutuksesta (2,5 milj. tonnia). Raaka-aineena käytetään mäntyöljyä, jota saadaan sellunvalmistuksen sivutuotteena.

Nesteen Porvoon jalostamon NExBTL kapasiteetti on 170 000 tonnia vuodessa. Melkein mikä tahansa kasviöljy tai eläinrasva kelpaa raaka-aineeksi.

Yhdessä näillä yksiköillä voidaan tuottaa noin 10 % maan dieselin kulutuksesta.

Lisäksi Finnpulp suunnittelee Kuopioon havusellutehdasta, joka tuottaisi sellun ohessa 60 000 tonnia mäntyöljyä vuodessa.

http://www.upmbiopolttoaineet.fi/bi...-lappeenrannan-uusi-laitos/Pages/Default.aspx

https://www.neste.com/fi/fi/puhtaammat-ratkaisut/tuotteet/uusiutuvat-polttoaineet

http://www.finnpulp.fi/havusellutehdas-finnpulp.html

https://fi.wikipedia.org/wiki/Biodiesel

Ei ollut taipuva patteri Samsungin ainoa yllätys

https://techcrunch.com/2017/01/09/n...s-300-miles-of-range-from-a-20-minute-charge/Samsung’s SDI battery subsidiary announced a new battery cell designed for use in electric vehicles that offers improved density to manage a max range of up to 372 miles on a full charge, with a quick charge capacity that will help it regain 310 miles or so of charge on just 20 minutes of charging. Unveiled at the North American International Auto Show for the first time, the new battery tech come with a 10 percent decrease in the number of units and weight required vs. current production battery units made by Samsung SDI.

Mass production isn’t set to begin until 2021, but the tech should arrive in time to supply the first crop of autonomous cars, which are also targeting street dates sometime within that year from a range of manufacturers. EV and self-driving are tied closely to one another, since both are crucial components for operating the kind of on-demand ride-sharing fleets planned by Ford, among others.

A 20-minute charge delivering that kind of range would help considerably with making EVs more practical for more drivers; it’s around the time you’d spend at a rest stop using the restroom and grabbing coffee or a snack, after all. By comparison, Tesla’s superchargers currently manage to provide around 170 miles of range on a half-hour charge, so Samsung’s planned tech could approximately double that.

Tesla’s long-term goal, according to CTO JB Straubel at the time of the Supercharger’s first unveiling, is to get charging times down to between five and 10 minutes, and it has been quietly boosting the maximum theoretical output of the stations themselves (though Tesla vehicle batteries are still limited to 120 kW in terms of how much power input they can accept).

Tesla produces its own batteries in partnership with Panasonic, and just began construction on its latest generation cells at its Gigafactory in Nevada, while Samsung’s new 21700 cylinder cell model is currently being used by “U.S. automobile startups” in their EVs, according to Samsung SDI. One of those startups is Lucid Motors, a new EV company with a lot of Tesla talent on board.

http://www.spacedaily.com/reports/S...tion_conditions_using_compact_lasers_999.htmlUntil now, recreating the conditions inside a star required the use of massive lasers -- lasers the size of football stadiums. Experiments at Colorado State University suggest compact lasers can be manipulated to produce similarly extreme conditions.

At sea level, humans experience a single atmosphere of pressure. The energy density inside a stellar core measures in the billions of atmospheres. Recreating these intense conditions is difficult.

Recently, scientists realized they could recreate intense stellar pressure using much smaller lasers by hitting nanowire arrays with ultra-short laser pulses. Researchers measured the X-rays emitted by the irradiated arrays, which revealed the penetration of extreme energies within the microstructures of the nanowires.

Scientists used the results to build numerical models, while predicted more intense irradiation produced by more powerful -- but still compact -- ultrafast lasers would be sufficient to generate pressure more intense than the center of the sun.

The breakthrough -- detailed in the journal Science Advances -- could make high energy and density physics accessible to researchers without assess to the world's biggest lasers. The work could provide a boost to researchers working on ways to generate nuclear fusion using lasers.

Illustration: UT Austin/IEEE Spectrum

http://spectrum.ieee.org/energywise...he-full-cost-of-electricity-know-your-historyFor decades, scale economies associated with large, centralized, electricity generation technologies encouraged vertical integration. It also drove down the cost of electricity, fostered universal access, and provided for reliable electric service delivered by a single utility in a given region. That practice gave us the now traditional, vertically integrated, electric utility model.

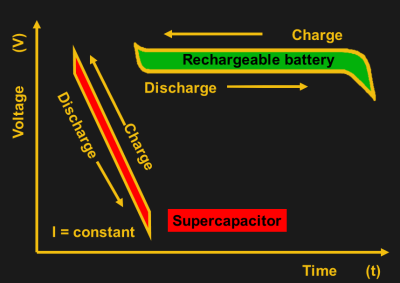

Hyvä ja selkeä esitys superkondensaattoreista.

http://hackaday.com/2017/01/19/will-supercapacitors-ever-replace-batteries/Recharging your mobile phone or your electric vehicle in a few minutes sure sounds appealing. Supercapacitor technology has the potential to deliver that kind of performance that batteries currently can’t, and while batteries are constantly improving, the pace of development is not very fast. Just remember your old Nokia mobile with Ni-Cad batteries and several days of usage before a recharge was needed. Today we have Lithium-Ion batteries and we have to charge our phones every single day. A better energy storage option is clearly needed, and supercapacitors seem to be the only technology that is close to replace the battery.

Supercapacitors already have several niche applications, with an estimated $400 million world market. Memory backup and protection was one of the first applications, as well as for powering electronic toys. They are also used in solar arrays and for micro energy harvesting systems. At the high end of the energy storage spectrum, supercaps are used in hybrid electric vehicles for regenerative braking and to provide starting power. The power grid can also benefit from them, using banks of supercaps as a buffer for power surges, the transmission lines can operate closer to a 100% capacity, increasing efficiency.

All of this is good news, and supercaps have begun to take on some roles traditionally assigned to batteries. But supercaps still lag behind batteries in terms of storage. New advances in technology, such as the use of graphene and other compounds, may increase capacity in the near future, making the supercapacitor a real option to replace the battery. For now, manufacturing remains expensive, and physical size means that even if you are willing to splurge on price you still can’t get a reasonable replacement for today’s Li-ion toting mobiles. Perhaps the next trend in smartphones will be a return to the brick design, making room for supercaps to utilize their rapid charging and long service life. Until then we wait for manufacturing advancements that can fit larger plates into a smaller space.

http://www.spacedaily.com/reports/Faster_recharging_batteries_possible_after_new_insights_999.htmlFaster recharging lithium batteries could be developed after scientists figured out why adding charged metal atoms to tunnel structures within batteries improves their performance.

Rechargeable lithium batteries have helped power the 'portable revolution' in mobile phones, laptops and tablet computers, and new generations of lithium batteries are being developed for electric vehicles and to store energy from wind and solar power.

Now the research groups of Professor Saiful Islam of the Department of Chemistry at the University of Bath, and Professor Reza Shahbazian-Yassar at the University of Illinois at Chicago, have gained important insights to help improve the performance of lithium batteries, published in the leading journal Nature Communications.

Storing electrical energy more quickly than current electrodes is important for future applications in portable electronics and electric vehicles.

It was recently discovered that that large metal ions such as potassium can improve charge storage in batteries, but it wasn't understood why this was the case.

The research teams used a powerful combination of structural experiments and computer simulations to unravel for the first time why adding charged potassium into tunnel-like structures of low-cost manganese oxide has a strong beneficial effect on the battery performance.

They discovered that adding positively charged ions increased how fast lithium moves within the tunnel structures, which is crucial to improving the charging of batteries.

Professor Islam said: "Understanding these processes is important for the future design and development of battery materials, and could lead to faster charging batteries that will benefit consumers and industry.

"Developing new materials holds the key to lighter, cheaper and safer batteries, including for electric vehicles which will help cut carbon emissions."

http://www.nature.com/articles/ncomms13374

https://thinkprogress.org/chart-of-...ut-in-half-since-2014-718752a30a42#.v4lz71xqbBattery prices have continued their stunning decline, with game-changing implications for electric vehicles (EVs), the electric grid, and the cage fight between renewables and natural gas.

Bloomberg New Energy Finance (BNEF) reports that lithium-ion battery prices have fallen “by almost half just since 2014” and “electric cars are largely responsible.” Last year, BNEF called this “the miracle of Musk,” referring to Elon Musk, the CEO of Tesla, which jump-started the stagnant EV business and whose gigafactory will keep putting downward pressure on battery costs.

In 2013, the International Energy Agency estimated EVs would achieve cost parity with gasoline vehicles when battery costs hit $300 per kiloWatt-hour of storage capacity, which the IEA said would happen by 2020. That price point was in fact crossed last year, which is why both GM and Tesla announced they could deliver affordable (well below $40,000), long-range (200-plus miles) EVs.

“Batteries capable of storing power at utility scale will be as widespread in 12 years as rooftop solar panels are now,” predicts BNEF. Over the next 25 years, small-scale battery storage will become a $250 billion market.

This in turn will drive “peak fossil fuels for electricity.” Bottom line: “Coal and gas will begin their terminal decline in less than a decade.” Similarly, EVs will likely drive peak oil demand in the 2020s, too.

Tragically, we have a president who is beholden to the dirty fuels of the past like coal and oil, and who is poised to cede millions of high-wage clean energy jobs to China and other countries.

https://www.bloomberg.com/news/arti...battery-revolution-just-reached-critical-massTesla Motors Inc. is making a huge bet that millions of small batteries can be strung together to help kick fossil fuels off the grid. The idea is a powerful one—one that’s been used to help justify the company’s $5 billion factory near Reno, Nev.—but batteries have so far only appeared in a handful of true, grid-scale pilot projects.

That changes this week.

Three massive battery storage plants—built by Tesla, AES Corp., and Altagas Ltd.—are all officially going live in southern California at about the same time. Any one of these projects would have been the largest battery storage facility ever built. Combined, they amount to 15 percent of the battery storage installed planet-wide last year.

Ribbons will be cut and executives will take their bows. But this is a revolution that’s just getting started, Tesla Chief Technology Officer J.B. Straubel said in an interview on Friday. “It’s sort of hard to comprehend sometimes the speed all this is going at,” he said. “Our storage is growing as fast as we can humanly scale it.”

http://www.terradaily.com/reports/C...makes_water_splitting_more_efficient_999.htmlOne of the main obstacles in the production of hydrogen through water splitting is that hydrogen peroxide is also formed, which affects the efficiency stability of the reaction and the stability of the production. Dutch and Israelian researchers from Eindhoven University of Technology and the Weizmann Institute have succeeded in controlling the spin of electrons in the reaction and thereby almost fully suppress the production of hydrogen peroxide.

They published these findings this week in the Journal of the American Chemical Society. The efficient production of hydrogen paves the way towards water splitting by solar energy.

Hydrogen has been referred to as the fuel of the future but its generation is still not efficient enough. One of the production methods is a photo-electrochemical cell whereby water is split into hydrogen and oxygen under the influence of light. Not only does the reaction require a lot of energy but also hydrogen peroxide is formed as a by-product, leading to the poisoning of one of the electrodes and thus reduced efficiency.

10 vuotta kestävä nestemäinen flow patteri

https://www.engadget.com/2017/02/12/flow-battery-lasts-for-10-years/Modern batteries aren't hampered so much by their capacity as their long-term lifespan -- a lithium-ion pack can easily become useless after a few years of heavy use. That's bad enough for your phone, but it's worse for energy storage systems that may have to stick around for the long haul. If Harvard researchers have their way, you may not have to worry about replacing power backs quite so often. They've developed a flow battery (that is, a battery that stores energy in liquid solutions) which should last for over a decade. The trick was to modify the molecules in the electrolytes, ferrocene and viologen, so that they're stable, water-soluble and resistant to degradation. When they're dissolved in neutral water, the resulting solution only loses 1 percent of its capacity every 1,000 cycles. It could be several years before you even notice a slight dropoff in performance.

The use of water is also great news for both the environment and your bank account. As it's not corrosive or toxic, you don't have to worry about wrecking your home if the battery leaks -- you might just need a mop. The safer materials are also less expensive than the polymers you usually need in flow batteries, and wouldn't require exotic pumps and tanks to withstand harsher chemicals. It needs less maintenance than other flow designs, too.

There's no concrete roadmap for bringing this battery tech to the real world. There's definitely a market for it, though. Renewable energy is becoming increasingly cost-effective, and inexpensive, long-lasting batteries would only help that. You could install solar power at home knowing that the cost of energy storage won't wipe out the money you save on your electricity bill.

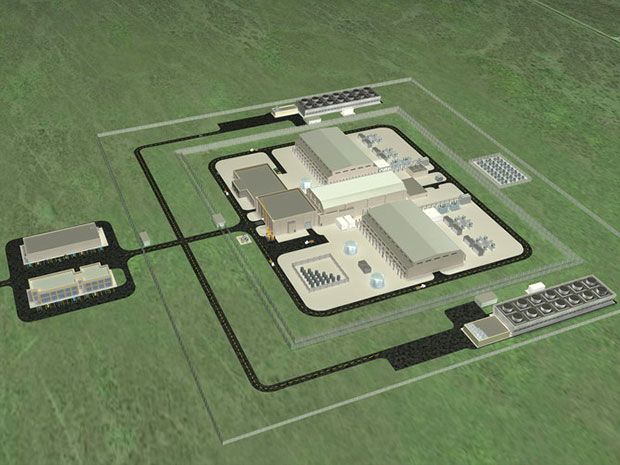

http://spectrum.ieee.org/energywise...-design-nears-a-milestone-with-more-to-followSmall modular reactors are defined as nuclear reactors delivering 300 megawatts of electric power equivalent or less. They are designed to include modular technology and use factory fabrication techniques that offer the promises of economies of scale and shorter construction times.

SMR designs include water-cooled reactors, high temperature gas-cooled reactors, as well as liquid metal cooled reactors with fast neutron spectrum. Some SMRs, like NuScale’s advanced light-water reactor, are designed to be deployed as multiple-module power plants.

In paractice, each 50 MW NuScale module is intended to be a self-contained unit that operates independently within a multi-module configuration. Up to 12 of the 50-MW modules can be monitored and operated from a single control room. Each reactor measures 17.1 meters tall and 2.7 meters in diameter, and sits within a containment vessel.

Nojatuolistrategi

Ylipäällikkö

Biomassasta ja minireaktoreista:

VTT Oy:n johtaja Satu Helynen ja Gaia Consulting Oy:n johtava asiantuntija Mikko Kara kirjoittavat Talouselämässä energian tuotannon tulevaisuudesta ja uusista SMR-ydinreaktoreista. Suomessa metsistä saatava bioenergia on rajallinen energialähde. EU:n niin kutsuttu talvipaketti on myös kiristämässä biomassan kestävyyskriteereitä ja rajoittaa samalla sen käyttöä. Hajautettuun energian tuotantoon on asiantuntijoiden mukaan tulossa uusi vaihtoehto. Pienten, modulaarisesti rakennettavien ydinreaktorien kehitys on pitkällä USA:ssa, Venäjällä ja Kiinassa. USA ja Iso-Britannia arvioivat kaupallistavansa SMR-laitokset 2020-luvun loppuun mennessä. http://www.verkkouutiset.fi/kotimaa/SMR_ydinvoimalat-62099

Ydinreaktori joka niemeen notkoon ja saarelmaan?

VTT Oy:n johtaja Satu Helynen ja Gaia Consulting Oy:n johtava asiantuntija Mikko Kara kirjoittavat Talouselämässä energian tuotannon tulevaisuudesta ja uusista SMR-ydinreaktoreista. Suomessa metsistä saatava bioenergia on rajallinen energialähde. EU:n niin kutsuttu talvipaketti on myös kiristämässä biomassan kestävyyskriteereitä ja rajoittaa samalla sen käyttöä. Hajautettuun energian tuotantoon on asiantuntijoiden mukaan tulossa uusi vaihtoehto. Pienten, modulaarisesti rakennettavien ydinreaktorien kehitys on pitkällä USA:ssa, Venäjällä ja Kiinassa. USA ja Iso-Britannia arvioivat kaupallistavansa SMR-laitokset 2020-luvun loppuun mennessä. http://www.verkkouutiset.fi/kotimaa/SMR_ydinvoimalat-62099

Ydinreaktori joka niemeen notkoon ja saarelmaan?

Miinus asteilla toimiva Solid State patteri.

http://hackaday.com/2017/03/05/solid-state-battery-from-the-man-who-brought-us-lithium-ion/The battery relies on solid glass electrolyte. It also employs an alkali metal anode to realize increased energy density of the cathode. The electrolyte can operate down to -20 degrees C, which is unusual for a solid state battery.