T-80: the workhorse of the Russian army

DAMIAN RATKA

12/26/2022 11:37

photo. Vitaly V. Kuzmin/CC BY-SA 4.0

The T-80 MBT was developed in the 1970s in the USSR during the intricate vicissitudes of the Soviet MBT production program as a gas turbine-powered evolution of the T-64A. It was considered expensive to operate, produced in smaller quantities than competitors and was treated after the collapse of the USSR as a machine with no prospects. Meanwhile, it is one of the most popular tanks currently used by the land forces of the Russian Federation.

T-80

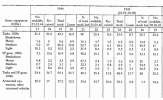

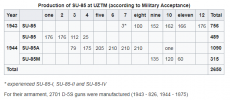

Work on gas turbines as a drive for tanks began in the USSR in 1949, under the direction of engineer A. Ch. Starostenko at the plants named after Kirov in then Leningrad, but they were discontinued due to the low quality of engines available at the time. They were resumed in 1955, under the direction of engineer GA Ogloblin, and resulted in the creation of two prototype 1000 hp drive units. At that time, it was assumed that a gas turbine would be the preferred drive for heavy tanks, because these engines, with relatively low weight and small dimensions, have high power and adequate torque.

The T-80 was the world's first mass-produced tank whose main drive was a gas turbine. It is worth paying attention to the turret, which is almost identical to the turret of the T-64A tank. photo.

Vitaly V. Kuzmin/CC BY-SA 3.0

After the deletion of the heavy tank programs, during the work on the new generation Object 432 tank, which was put into service as the T-64, initial work on the gas turbine variant, designated as the T-64T (Object 003) with the GTD-3TL gas turbine, began with a power of 700 hp. Over time, the project was transferred to the plants of Kirov, where under the leadership of SP Izotowa from the construction office of Klimow, work has begun on a new GTD-1000T gas turbine with a capacity of 1000 HP. The T-80 is characterized by a weight of 42 tons, which, with a 1000 HP engine, allows it to reach speeds on paved roads of up to 70 km/h, with an operational range of 500 km.

The tank to be powered by a new gas turbine was designated Object 219 Sp1 and was a development version of the T-64A (Object 434), work on it was led by NS Popov. During the tests, it turned out that the Object 219 Sp1, which was basically a T-64A tank with a different engine, did not perform very well. This was due to the suspension getting into excessive vibration and generating excessive noise. This required changes in the suspension and, by the way, the geometry of the hull was changed and changes were made to the design of the driver's periscope, replacing one large one with three smaller ones.

The next prototype was designated Object 219 Sp2, and subsequent prototypes were based on it until the serial version. The new tank was designated as the T-80, but already at the time of its introduction into service in 1976, it was in many ways outdated and in need of modernization. First of all, although the car inherited a turret based on the one used in the T-64A, in the first T-80s it lacked composite armor. It was the so-called monolithic turret, as was the case with the T-72 Ural tanks and some T-72 Ural-1 examples. The thickness of her armor ranged from 465 mm to 635 mm depending on the location and angle of measurement.

Over time, a turret with one of the two variants of composite armor used in the T-64A tank was probably introduced. It could have been variant number 1, in which high-hardness steel plates were used, placed in chambers at the front of the turret, or a variant with ceramic balls embedded in cast steel in the casting process, which, after cooling, formed the shell of the turret. The thickness of variant number 1, depending on the place and angle of measurement, ranges from 433 mm to about 635 mm, in the case of variant number two, the thickness ranged from 465 mm to 635 mm.

Composite armor was also used on the front of the hull, but here it was also characterized by an aging 80 mm steel + 106 mm glass textolite + 20 mm steel arrangement, this arrangement was sloped at an angle of 68°, giving an effective thickness of 549 mm.

Secondly, the T-80, like the T-64, T-64A and T-72, did not have an FCS as such, but only a sighting system with an optical rangefinder. The optical rangefinder sight is marked TPD-2-49 and already in the second half of the 1970s it was obsolete compared to the laser rangefinder sights entering service. Also the TPN-1-49-23 night vision device was already obsolete and needed to be replaced with a more modern solution ensuring better night vision. The commander received an observation cupola with the TKN-3M "Crystal" device, which has both day optics and a night vision aided by an OU-3GA2 or OU-3GKU infrared searchlight. When it comes to communication, the vehicles received the R-123M radio and the R-124 intercom.

The main armament is a 125 mm 2A46-1 smoothbore cannon loaded by the EC10M loading mechanism located under the turret with a supply of 28 rounds of split ammunition in the loading mechanism magazine and an additional 12 sets of shell + propelling charge in the hull. Additional armament is only a 7.62 mm PKT machine gun coupled with the cannon with a supply of 1250 7.62x54R mm rounds.

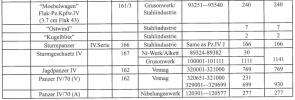

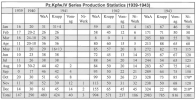

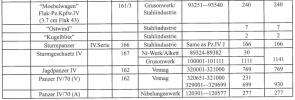

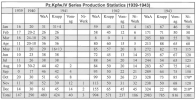

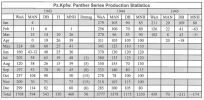

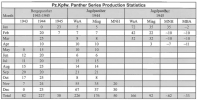

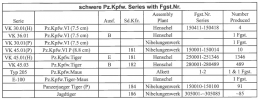

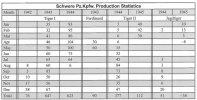

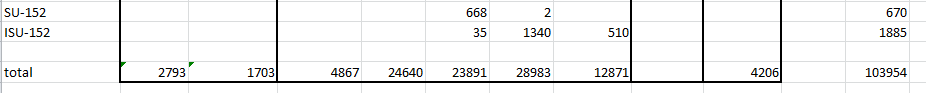

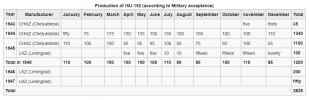

In total, between 1976 and 1978, about 130-250 T-80 tanks were produced.

T-80B

Among other things, for these reasons, the T-80 was only produced from 1976 to 1978, when it was replaced by the improved T-80B (Object 219R), which had improved armor protection. In the case of the hull, a new layout was used: 60 mm of steel + 100 mm of glass textolite + 45 mm of steel, which at an angle of 68° gives an effective thickness of 547 mm and, despite a slightly lower overall thickness, thanks to a thicker plate ending the system, it is more effective. In 1982, as part of the Reflection-1 program, a modification was introduced to the structure of the front hull armor by welding a 30 mm thick high-hardness steel plate, which was to improve protection against modern APFSDS ammunition for 105 mm guns, until a new armor system was developed under program Reflection-2.

The T-80B also received a new turret, in which the so-called quartz core, as in some of the T-72 Ural-1 and T-72A tanks and its export version T-72M1, the thickness of the turret ranges from 520 mm to 715 mm depending on the location and angle of measurement.

The T-80B was an analogue of the T-64B, but the machine was more expensive to manufacture and operate due to the GTD-1000TF gas turbine drive.

photo.

Vitaly V. Kuzmin/CC BY-SA 3.0

The T-80B, like the T-64B, was also equipped with the most modern tank fire control system in the world in the 1970s, the 1A33 "Ob". This system consists of a day sight - a laser rangefinder 1G42, which is important, this sight has a mirror stabilized both vertically and horizontally. In addition, the vehicle has a digital ballistic computer 1W517, a wind speed sensor 1B11 and an air temperature sensor 1B14. In 1978, no mass-produced western tank had a comparable fire control system, although this advantage of the USSR was short-lived because in 1979 the production of M1 and Leopard 2 tanks began in the USA and West Germany.

For observation and combat at night, the gunner had the TPN-3-49 night sight supported by the Ł-4A Luna infrared searchlight. for the 9M112 "Kobra", 9M124 and 9M128 "Agona" anti-tank guided missiles fired from the cannon. The missiles are controlled by radio command using the GTN-12 antenna.

The main armament is an improved 2A46-2 or 2A46M-1 cannon, loaded by the modernized 6EC40 loading mechanism, also with a reserve of 28 sets of missile + propellant in the magazine under the turret, and a reserve of 10 sets of missile + propellant in the hull. Additional armament consists of a PKT machine gun and a 12.7 mm NSWT machine gun with a supply of 300-350 rounds of 12.7x108 mm, located at the commander's observation cupola, in the ZU-80 position.

An improved GTD-1100TF engine with 1,100 hp was also introduced, thanks to which, despite the increase in weight to 42.5 tons, it allowed to maintain a maximum speed of 70 km/h on paved roads and an operational range of 500 km.

The T-80B was one of the most-produced variants of the T-80 tank, with approximately 4,352 units produced between 1978 and 1985.

T-80BV

In 1985, a new variant of the T-80B tank, designated T-80BV (Object 219RV), was introduced into production, in which modifications were made to improve armor protection. First of all, in accordance with the results of the research and development work code-named Reflection-2, a new layout of the front hull armor was introduced, which was as follows: 50 mm steel + 35 mm glass textolite + 50 mm steel + 35 mm glass textolite + 50 mm steel. The structure and cover of the turret remained unchanged.

T-80BV

Vitaly V. Kuzmin

In addition, the implementation of the effects of the research and development program code-named "Lis" conducted at NII Stal under the leadership of DA Rototajew was started. The result of this work was the implementation of the Kontakt-1 explosive reactive armor with 4S20 reactive elements. These modules are located in the front of the hull, on the front and roof of the turret and on the sides of the shelves above the tracks. In addition, the modules were to be placed on the side skirts of the hull, but due to their delicate structure and the weight of the modules, the skirts were deformed and damaged, as a result of which this solution was abandoned, while significantly reducing the level of protection.

The use of Kontakt-1 high-explosive reactive armor significantly increased the vehicle's resistance to single HEAT rounds, but did not improve protection against tandem HEAT rounds and APCR rounds.

It is not known exactly how many T-80B tanks were brought to the T-80BV version, or how many new T-80BV tanks were produced. However, in the documents of the CFE Treaty of October 1990, west of the Ural Mountains, there were 594 T-80BV tanks and 23 T-80BVK tanks, which accounted for 13% of the entire fleet of T-80 tanks.

The car required further, deep modernization and such a program had been underway since the mid-1970s.

T-80U and T-80UD

The new generation of T-80 tanks was to be created as an amalgamation of various projects carried out by various design offices. The key was the program of deep modernization of T-64B tanks (Object 447A), codenamed Object 476 "Cedar". The project focused on improving several key characteristics of the vehicle. First, a new turret design was developed with new special armor based on a cast shell with chambers in the front part that housed steel packages with cells filled with a polymer, most likely polyurethane. The thickness of the front armor varies from 435 mm to 825 mm depending on the location and angle of measurement.

The front hull armor was also modernized, bringing it to the standard of the T-72A or T-80B tanks, i.e. it is a 68° inclined arrangement of 60 mm steel + 106 mm glass textolite + 50 mm steel or 60 mm steel + 100 mm textolite glass + 45 mm steel, so an effective thickness of 576 mm or 547 mm.

Another significant modification was the use of a new diesel engine, it was a two-stroke unit with counter-rotating pistons 6TD-1 with 1000 hp, which was the successor of the 700 hp 5TDF engine used in tanks of the T-64 family.

Eventually, Object 476 was abandoned, but the time and money invested in this project were not wasted. In Kharkiv, the 6TD-1 engine was further developed for a new project, Object 478, which combined the turret of the Object 476, also under development, with a modified T-80B tank hull.

Meanwhile, in Leningrad, further work on the development of T-80B tanks, codenamed Object 219A, began. Over time, a decision was made to unify the designs and implement one tank with two different types of propulsion, i.e. the gas turbine-powered T-80U (Object 219AS) and the T-80UD diesel engine (Object 478B).

It should also be mentioned that a new engine was also being developed for the T-80U. It was to be a new gas turbine with reduced fuel consumption, designated WGTD-1000FM. The task set before the engineers turned out to be extremely difficult to implement, the engine was unreliable and failed any of the tests, which delayed the work and basically failed to meet any deadline for the turbine to undergo state tests. For this reason, it was decided to use a modified GTD-1100F engine, which was pushed to 1250 hp, and became the basis for the final GTD-1250 engine.

Both vehicles were to have unified composite armor of the turret and hull, in the case of the turret, the solution related to cells filled with polymer was refined. It should be noted, however, that in the course of production, the T-80UD also replaced the turret's composite armor, made of polymer-containing cells, with steel-ceramic layers. There were more changes to the hull. Initially, an armor layout was introduced identical to the T-80BW produced from scratch. Over time, however, the shield was modified, it was still inclined at an angle of 68 °, but it was to appear in two new versions implemented from 1986, in the T-80U it was 51 mm of steel + 35 mm of glass textolite + 31 mm of steel + 20 mm of air chamber + 35 mm glass textolite + 50 mm steel.

The T-80UD uses a more advanced solution, namely 55mm steel + 35mm ceramic + 35mm steel + 5mm air chamber + 35mm ceramic + 50mm steel. Both the turret and the hull also received additional protection in the form of fixed Kontakt-5 explosive reactive armor modules with 4S22 reactive elements.

Both tanks are equipped with the new 1A45 "Irtysh" fire control system, with the 1G46 day laser rangefinder and the TPN-4 Buran-PA night sight, which is supported by the Ł-4A Luna infrared searchlight. The vehicle is also equipped with a new 9K119 guided weapon system with cannon-launched 9M119 "Refleks" or 9M119M "Inwar" anti-tank guided missiles.

The main armament is the 2A46M-4 cannon, loaded by the 6EC43 loading mechanism, which, like its predecessors, stores 28 sets of projectile + propellant charge in the magazine under the turret, the secondary ammunition is 17 sets of projectile + propellant charge located in the turret and hull. Additional armament consists of a standard PKT machine gun coupled with the cannon and a NSWT large-caliber machine gun operated by the commander.

Apart from the engine, the difference between the T-80U and T-80UD is also in the commander's observation cupola, which was initially supposed to be unified, but in the end, due to the faction fighting typical of the USSR armaments industry, two different solutions were used. Let's start with the T-80UD, which is considered more advanced. The commander has a fully stabilized 1EC29 observation cupola with a machine gun station remotely controlled from the inside. It has the PNK-4 sighting system with the TKN-4S "Agat" day and night sighting device and the PZU-7 machine gun sight. What's more, the cupola is equipped with the function of doubling the controls of the turret and the main armament, thanks to which the commander can not only indicate targets to the gunner in the "hunter killer" mode, but also conduct fire himself.

The T-80UE-1 is a hybrid of the T-80BV hull upgraded to the T-80U standard with the turret of the T-80UD tank. On the turret, the 1EC29 commander's observation cupola with a remotely controlled machine gun position is visible. photo. Vitaly V. Kuzmin/CC BY-SA 4.0

In the T-80U, a simpler solution was used, i.e. the observation cupola has all the above-mentioned functions, except for the machine gun remotely controlled from inside, instead of which there is a solution that can be considered at least strange. Namely, on the ceiling of the tower, there are 4 bases on which one or more NSWT machine guns can be placed.

The operation of these positions is at least inconvenient, and it should be stated directly that it is extremely dangerous for the commander, because it requires not only opening the hatch and exposing the torso, but almost completely leaving the turret. It depends exactly on which position the machine gun is installed at the moment.

T-80U tank, this photo clearly shows the not very rational construction of the commander's machine gun position.

photo. Vitaly V. Kuzmin/CC BY-SA 3.0

The vehicle also received a new R-173 communication system with an R-174 intercom.

In the 1980s, the T-80U and T-80UD were the best, most advanced and most expensive tanks produced in the USSR. They were used by the most elite units, such as the 4th Kantemirovskaya Armored Division. They were also produced relatively few, although it is not known exactly how many, it is estimated that in the amount of about 3,000 T-80U in the years 1984 - 1997. T-80UD tanks were produced, it is estimated, about 500-800 units.

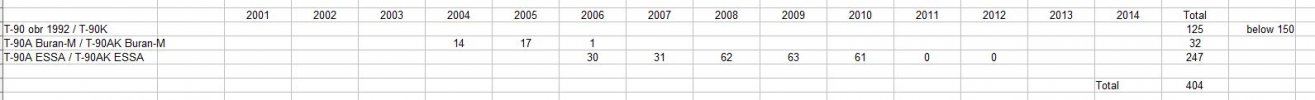

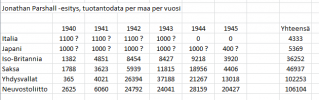

Modernization of T-80 tanks in the 21st century

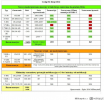

In the 21st century, it became clear to the Armed Forces of the Russian Federation that their fleet of tanks needed modernization. This also applied to the T-80 family vehicles, in particular the most frequently used T-80B and T-80BV versions. The research and development work was code-named "Motobol" and was divided into several stages.

The modernization of these tanks is a multi-stage process, as several different directions of development have been undertaken. The first is the T-80UE-1, which is a de facto hybrid of two tanks. The Russian Federation inherited a fairly large fleet of T-80UD tanks from the USSR, but the problem with maintaining these machines was their engines - the 6TD-1 produced in Kharkiv.

Replacing the engine is not a cheap and simple operation, so it was decided to upgrade some of the T-80BV tank hulls to the T-80U standard, and mount the T-80UD tank turrets on them, thus creating the T-80UE-1 (Object 219AS-1 ). The turrets themselves have also been modernized to some extent, through improvements in the fire control system, mainly in terms of the ability to fight at night and in difficult weather conditions, or through the installation of a passive-active Buran-M night observation and targeting device with a PŁ-1 laser emitter instead of the Ł-4A infrared searchlight (some T-80U tanks received similar modifications). Alternatively, some of the vehicles received Plisa thermal imaging cameras.

The 2A46M-1 cannon was also replaced with a more modern 2A46M-4. The loading mechanism was upgraded to the 6EC43-2S model, which allows the use of more modern ammunition, including APFSDS with an extended core and new programmable fuses of the "Ainet" system for high-explosive ammunition.

Similar modifications were introduced in the modernized T-80U vehicles to the T-80UA and T-80UM standards, but these machines, like the T-80UE-1, were few, most likely their total number does not exceed 100 copies.

photo. mil.ru

In the end, it was decided to modernize the T-80B and T-80BV tanks more economically, which would not require a deep reconstruction of the vehicle and significant interference in its construction, the new variant was designated T-80BVM. Due to the technological process of turret production, it is impossible to replace it with a more modern, composite armor, a similar problem occurs in the case of the hull, where, although it is a welded structure, its geometry makes such replacement difficult.

Therefore, it was decided to strengthen the armor protection by installing modules of the new Relikt explosive reactive armor with 4S23 reactive elements. This solution does not interfere with the structure of the vehicle, at the same time it is relatively cheap, simple and has a relatively low weight and good efficiency. Interestingly, some of the vehicles also received the so-called soft modules of explosive reactive armor, in the form of webbing containers attached to the side skirts of the hull. This solution allows to increase the protection of the sides of the hull.

Another important point of modernization was the replacement of the SKO. The old 1A33 system was replaced with a modern digital fire control system based on the PNM Sosna-U multi-channel sight with a daylight channel and a thermal imaging channel, a laser rangefinder and a coded laser beam emitter of the 9K119 system for the 9M119/9M119 "Refleks/Inwar" missiles. A new R-168-25U-2 "Akwedukt" communication system and an R-168 intercom were also installed.

The above improvements, of course, increased the weight of the car to 45.7 tons, hence the modernization of the drive was required by installing a more powerful GTD-1250 gas turbine with a power of 1250 hp, which means that this car can accelerate to 80 km/h on a paved road, and its operational range is about 500 km.

In general, before February 24, 2022, about 300 tanks were upgraded to the T-80BVM standard, but it cannot be ruled out that the T-80B/T-80BV tanks will be upgraded to the T-80BVM standard in the future.

Summary

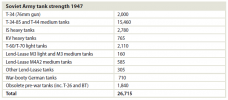

Despite the undeniable fact that the T-80 tanks were the most expensive mass-produced tanks in the USSR and still remain very expensive machines to operate for the Russian Armed Forces, these tanks, along with the T-72 tanks, are one of the pillars of the armored forces of the land forces.

photo. Vitaly Kuzmin/wikipedia.com/CC 3.0

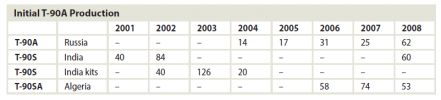

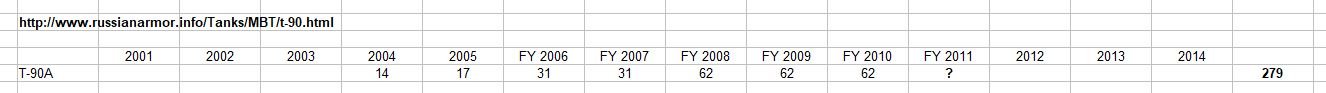

Before February 24, 2022, about 480 tanks were in active service, making the T-80 the second most heavily used tank type after about 2,000 T-72s and more than about 400 T-90A and T-90M tanks. It is also worth noting that the T-80BV tanks and the captured T-80U and T-80UE-1 tanks, constituting a fairly important element of Ukraine's armored arsenal, next to the numerically dominant T-64 and T-72 vehicles.

Special vehicles based on the chassis of the T-80 tank should not be forgotten, such as the 2S7 Pion self-propelled howitzers, the 2S19 Msta-S self-propelled gun-howitzers, the BREM-80U recovery vehicle, the S-300V air and missile defense system carrier, the PTS-4 amphibious vehicle and other specialized vehicles. caterpillar traction vehicles.

S-300VM kit. photo. Vitaly V. Kuzmin/CC BY-SA 4.0

Despite the quite significant losses incurred, as 190 T-80BV tanks, 1 T-80BVK tank, 89 T-80U, 2 T-80UK, 8 T-80UE-1, 62 T-80BVM tanks were confirmed destroyed, these tanks are still being repaired, in modernized as far as possible and sent to fighting formations, which makes them an important component of the land forces of the Russian Federation and these tanks should still be treated as very dangerous on the battlefield.