Antares

Respected Leader

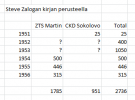

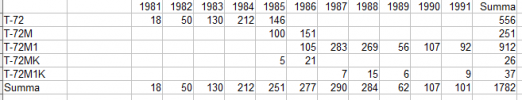

Loput edellisen viestin artikkelista:

Almost immediately after the end of the war, Škoda began to develop anti-aircraft artillery, including automatic ones. Even during the war, Škoda developed a 50 mm automatic anti-aircraft gun, which was intended for the German army. After the war, this development continued to develop. The result of this work was a 50-mm automatic gun, which had frankly German roots. The gun, designed in 1948, was supposed to be mounted on a 50 mm ShPLK 2,12 / 1020-LP ZSU , based on a redesigned Škoda T-17 chassis. Neither the anti-aircraft gun nor the chassis for it advanced further than the paper.

A prototype ZSU based on the T-34, 1953

In 1949, the 57 mm R 8 anti-aircraft gun, a revised version of the same 50 mm anti-aircraft gun, was tested. Like the previous design, it was created with an eye on German developments. Power was supplied from metal clips with a capacity of 3 shots each. Ammunition R 8 differed from the Soviet 57-mm cartridges.

Later, the R 10 anti-aircraft gun appeared with a carriage modeled on the 40-mm Bofors anti-aircraft gun. The development of this system was delayed, only in 1956 the R 10 was put into service. The gun competed with the Soviet S-60 system with varying degrees of success, winning in some respects and losing in others. 220 R 10s were manufactured, and at the same time the Czechoslovak army also purchased S-60s. This was the only success of the Czechoslovak designers in the field of creating medium-caliber anti-aircraft systems. The larger anti-aircraft guns that Škoda developed did not go into production.

On the layout sample, the cabin was plywood

Against the backdrop of progress in work on the R 10, the question arose again of creating an anti-aircraft self-propelled gun. Due to the death of the Škoda T-17 and Škoda T 50 projects, the T-34-85 remained the only suitable base for it. On September 19, 1952, the VTU institute received an assignment to develop a ZSU using the T-34-85 chassis and the R 10 anti-aircraft gun. In addition to anti-aircraft functions, the vehicle was also assigned the task of combating weakly armored targets. After studying foreign experience, the VTU came to the conclusion that it was necessary to create an anti-aircraft tank like the English Crusader AA, the Swedish Landsverk Anti and its Hungarian derivative Nimrod. This simplified the task, since in this case it was not necessary to install a large platform and, accordingly, seriously alter the T-34-85 chassis.

For the calculation of 4 people, the tower was too small

When designing, it was required to keep the combat weight of the vehicle within the limits of the mass of the T-34-85. The task was complicated by the fact that the Czechoslovak military demanded that the frontal part of the anti-aircraft tower be protected from small-caliber artillery fire. In addition, the regular calculation of the gun consisted of 4 people (2 gunners, commander and loader). As a result, it was not possible to fully fit into the specified requirements. The combat weight of the T-34-85 turret, together with the gun, ammunition and crew, was 7820 kilograms, and the anti-aircraft turret weighed 8400 kilograms. The tower was made open from the stern and from above. In the frontal part, the thickness of the armor was 40 mm, and on the sides - 20 mm. However, the armor plates of the test sample of the anti-aircraft turret were made of plywood.

This ZSU did not pass the firing test

The results of the tests, which were carried out from March to July 1953, were not particularly good. The turret turned out to be too cramped, and the very idea of using the R 10 cannon as a weapon for the ZSU with minimal design changes turned out to be erroneous. The tower is too high. On August 29, 1953, work on this topic was stopped.

Self-propelled anti-aircraft gun LP-157, 1955

In 1955, the design office in Brno developed its own ZSU, this time made in the form of a full-size layout. Instead of the R 10 gun, it was supposed to install its improved version, which received the designation R 12. The designers made the ZSU LP-157 tower uninhabited. The ammunition was in the box to the left of the gun, and the calculation of three people (2 gunners and commander) was located below. This significantly reduced the size, and also reduced the combat weight. Also in Brno, a double-barreled version of the ZSU was developed, designated LP-257. A scale model of this machine was made.

However, the R 12 gun still needed to be built, and the time of the T-34-85 was coming to an end. In addition, the prospects for the purchase of the Soviet ZSU-57-2 loomed on the horizon. Work on the ZSU on the basis of the T-34-85 stopped, although the ZSU-57-2 was not included in the armament of the Czechoslovak army. Czechoslovakian wheeled ZSU Praga PLDvK vz. 53/59, built on the basis of the V3S truck, turned out to be, if not worse, then certainly simpler and cheaper.

Self-propelled rangefinder LV-157, with which the actions of the LP-157 were to be coordinated

The last Czechoslovak vehicle based on the T-34-85 was the mobile PUAZO (anti-aircraft artillery fire control device) LV-157. This machine was also developed in Brno and was intended to coordinate the fire of the ZSU LP-157. In fact, it was a self-propelled rangefinder, which was armed in the form of a quadruple DShK installation. Things did not progress further than a full-size layout built on the same chassis as the LP-157. Since the LP-157 and LP-257 projects were canceled, there was no need for a self-propelled rangefinder for them.

The appearance of the SD-100 and the Soviet SU-100 made it possible to partially solve the problem associated with the weak armament of the T-34-85. Since 1953, self-propelled guns began to enter service with tank regiments. The 85-mm S-53 gun could no longer effectively deal with new types of foreign tanks, and self-propelled guns were used as a means of reinforcement. In tank regiments, the share of the SU-100 began to account for a third of the total number of vehicles. The tanks replaced by the SD-100 were sent to storage bases.

SD-100 on exercises, mid-70s

Czechoslovak tank regiments remained mixed until 1960. Gradually, the place of the SD-100 and T-34-85 was taken by the T-54, which had a 100 mm gun, but in a turret, and even with much more serious protection. Now SD-100s have started to go to storage bases. In addition, they were actively offered to foreign buyers.

After the withdrawal from the tank regiments, the SD-100 was used as training vehicles until the mid-70s. It is not surprising that quite a lot of such machines have survived in the Czech Republic and Slovakia. SD-100 in many private and public collections in Europe play the role of the Soviet SU-100, here the comical situation with the G-13 was largely repeated. The difference is that the G-13 was still produced from the backlog of the Jagdpanzer 38 hulls, while the SD-100s were built in Czechoslovakia from scratch, and even in the mid-50s. For this reason, passing off such an ACS as a Soviet vehicle is not the best idea. But to some museums and collectors who are poorly versed in the topic, such cars are sold precisely as Soviet, military production. Such "Stradivarius drums" are not uncommon: museums in Munster, Sinsheim, La Wonseno and a number of other places have exactly the SD-100,

SD-100 parade in Cairo, 1957 The signs of self-propelled guns of Czechoslovak production are clearly visible

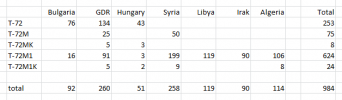

In total, the Czechoslovak army received 460 SD-100s out of 770 issued. The remaining SD-100s were built for export sales. On March 21, 1953, Antonin Zapototsky took the place of the deceased president of Czechoslovakia, Klement Gottwald. Under him, Czechoslovakia again became an active seller in the arms market. Already in 1953, sales began, and tanks were among the products offered. One of the first buyers was Egypt, where since 1955 the SD-100 began to arrive. It was Czechoslovak vehicles that were used by Egypt against the troops of Israel, England and France during the Suez conflict of 1956. The SD-100s at Bovington, Duxford and Saumur are all trophies from 1956. In total, Egypt received 148 SD-100s.

Israeli spoils of the Six Day War, 1967

In addition to Egypt, Syria acquired 38 SD-100s. These vehicles, like the Egyptian ones, were used in the 1967 Six Day War. Then the Israel Defense Forces pretty much replenished the collection of trophies. 100% of captured SU-100s in Israeli museums are SD-100s, which can be easily identified by their characteristic details.

The 1973 Yom Kippur War was the last in which the SD-100 fought en masse.

Later, deliveries of self-propelled guns from Czechoslovakia became mixed. In addition to the SD-100, a significant percentage were Soviet-made vehicles. Sometimes Czechoslovakia turned out to be only an intermediary between the USSR and other countries. For example, 50 SU-100s were delivered to Cuba from Czechoslovakia, but in fact these are Soviet vehicles. The situation is very similar with the 50th SU-100 that ended up in Yemen. The cars there are also clearly Soviet. Delivered SD-100 to Bulgaria, Romania, Ethiopia and Morocco.

Yuri Bakhurin

Czechoslovakian self-propelled guns in the Middle East

Photo review of the self-propelled guns SD-100 in the exposition of the Museum of the Israel Defense Forces

It's safe to say that the Czechoslovak military made the right choice with the SD-100. Although they did not succeed in producing tanks and self-propelled guns of their own design, they managed to solve the problem of arming the army with armored vehicles due to licensed production. In addition, thanks to the export deliveries of licensed cars, Czechoslovakia also managed to earn money. The country has again returned to the international arms market, albeit with combat vehicles not of its own design.

The author is grateful to Jiri Tintera and František Rozkot, Czech Republic, for their help in preparing the material.

Sources:

Self-propelled anti-aircraft gun on a medium base

Almost immediately after the end of the war, Škoda began to develop anti-aircraft artillery, including automatic ones. Even during the war, Škoda developed a 50 mm automatic anti-aircraft gun, which was intended for the German army. After the war, this development continued to develop. The result of this work was a 50-mm automatic gun, which had frankly German roots. The gun, designed in 1948, was supposed to be mounted on a 50 mm ShPLK 2,12 / 1020-LP ZSU , based on a redesigned Škoda T-17 chassis. Neither the anti-aircraft gun nor the chassis for it advanced further than the paper.

A prototype ZSU based on the T-34, 1953

In 1949, the 57 mm R 8 anti-aircraft gun, a revised version of the same 50 mm anti-aircraft gun, was tested. Like the previous design, it was created with an eye on German developments. Power was supplied from metal clips with a capacity of 3 shots each. Ammunition R 8 differed from the Soviet 57-mm cartridges.

Later, the R 10 anti-aircraft gun appeared with a carriage modeled on the 40-mm Bofors anti-aircraft gun. The development of this system was delayed, only in 1956 the R 10 was put into service. The gun competed with the Soviet S-60 system with varying degrees of success, winning in some respects and losing in others. 220 R 10s were manufactured, and at the same time the Czechoslovak army also purchased S-60s. This was the only success of the Czechoslovak designers in the field of creating medium-caliber anti-aircraft systems. The larger anti-aircraft guns that Škoda developed did not go into production.

On the layout sample, the cabin was plywood

Against the backdrop of progress in work on the R 10, the question arose again of creating an anti-aircraft self-propelled gun. Due to the death of the Škoda T-17 and Škoda T 50 projects, the T-34-85 remained the only suitable base for it. On September 19, 1952, the VTU institute received an assignment to develop a ZSU using the T-34-85 chassis and the R 10 anti-aircraft gun. In addition to anti-aircraft functions, the vehicle was also assigned the task of combating weakly armored targets. After studying foreign experience, the VTU came to the conclusion that it was necessary to create an anti-aircraft tank like the English Crusader AA, the Swedish Landsverk Anti and its Hungarian derivative Nimrod. This simplified the task, since in this case it was not necessary to install a large platform and, accordingly, seriously alter the T-34-85 chassis.

For the calculation of 4 people, the tower was too small

When designing, it was required to keep the combat weight of the vehicle within the limits of the mass of the T-34-85. The task was complicated by the fact that the Czechoslovak military demanded that the frontal part of the anti-aircraft tower be protected from small-caliber artillery fire. In addition, the regular calculation of the gun consisted of 4 people (2 gunners, commander and loader). As a result, it was not possible to fully fit into the specified requirements. The combat weight of the T-34-85 turret, together with the gun, ammunition and crew, was 7820 kilograms, and the anti-aircraft turret weighed 8400 kilograms. The tower was made open from the stern and from above. In the frontal part, the thickness of the armor was 40 mm, and on the sides - 20 mm. However, the armor plates of the test sample of the anti-aircraft turret were made of plywood.

This ZSU did not pass the firing test

The results of the tests, which were carried out from March to July 1953, were not particularly good. The turret turned out to be too cramped, and the very idea of using the R 10 cannon as a weapon for the ZSU with minimal design changes turned out to be erroneous. The tower is too high. On August 29, 1953, work on this topic was stopped.

Self-propelled anti-aircraft gun LP-157, 1955

In 1955, the design office in Brno developed its own ZSU, this time made in the form of a full-size layout. Instead of the R 10 gun, it was supposed to install its improved version, which received the designation R 12. The designers made the ZSU LP-157 tower uninhabited. The ammunition was in the box to the left of the gun, and the calculation of three people (2 gunners and commander) was located below. This significantly reduced the size, and also reduced the combat weight. Also in Brno, a double-barreled version of the ZSU was developed, designated LP-257. A scale model of this machine was made.

However, the R 12 gun still needed to be built, and the time of the T-34-85 was coming to an end. In addition, the prospects for the purchase of the Soviet ZSU-57-2 loomed on the horizon. Work on the ZSU on the basis of the T-34-85 stopped, although the ZSU-57-2 was not included in the armament of the Czechoslovak army. Czechoslovakian wheeled ZSU Praga PLDvK vz. 53/59, built on the basis of the V3S truck, turned out to be, if not worse, then certainly simpler and cheaper.

Self-propelled rangefinder LV-157, with which the actions of the LP-157 were to be coordinated

The last Czechoslovak vehicle based on the T-34-85 was the mobile PUAZO (anti-aircraft artillery fire control device) LV-157. This machine was also developed in Brno and was intended to coordinate the fire of the ZSU LP-157. In fact, it was a self-propelled rangefinder, which was armed in the form of a quadruple DShK installation. Things did not progress further than a full-size layout built on the same chassis as the LP-157. Since the LP-157 and LP-257 projects were canceled, there was no need for a self-propelled rangefinder for them.

Warrior Internationalist

The appearance of the SD-100 and the Soviet SU-100 made it possible to partially solve the problem associated with the weak armament of the T-34-85. Since 1953, self-propelled guns began to enter service with tank regiments. The 85-mm S-53 gun could no longer effectively deal with new types of foreign tanks, and self-propelled guns were used as a means of reinforcement. In tank regiments, the share of the SU-100 began to account for a third of the total number of vehicles. The tanks replaced by the SD-100 were sent to storage bases.

SD-100 on exercises, mid-70s

Czechoslovak tank regiments remained mixed until 1960. Gradually, the place of the SD-100 and T-34-85 was taken by the T-54, which had a 100 mm gun, but in a turret, and even with much more serious protection. Now SD-100s have started to go to storage bases. In addition, they were actively offered to foreign buyers.

After the withdrawal from the tank regiments, the SD-100 was used as training vehicles until the mid-70s. It is not surprising that quite a lot of such machines have survived in the Czech Republic and Slovakia. SD-100 in many private and public collections in Europe play the role of the Soviet SU-100, here the comical situation with the G-13 was largely repeated. The difference is that the G-13 was still produced from the backlog of the Jagdpanzer 38 hulls, while the SD-100s were built in Czechoslovakia from scratch, and even in the mid-50s. For this reason, passing off such an ACS as a Soviet vehicle is not the best idea. But to some museums and collectors who are poorly versed in the topic, such cars are sold precisely as Soviet, military production. Such "Stradivarius drums" are not uncommon: museums in Munster, Sinsheim, La Wonseno and a number of other places have exactly the SD-100,

SD-100 parade in Cairo, 1957 The signs of self-propelled guns of Czechoslovak production are clearly visible

In total, the Czechoslovak army received 460 SD-100s out of 770 issued. The remaining SD-100s were built for export sales. On March 21, 1953, Antonin Zapototsky took the place of the deceased president of Czechoslovakia, Klement Gottwald. Under him, Czechoslovakia again became an active seller in the arms market. Already in 1953, sales began, and tanks were among the products offered. One of the first buyers was Egypt, where since 1955 the SD-100 began to arrive. It was Czechoslovak vehicles that were used by Egypt against the troops of Israel, England and France during the Suez conflict of 1956. The SD-100s at Bovington, Duxford and Saumur are all trophies from 1956. In total, Egypt received 148 SD-100s.

Israeli spoils of the Six Day War, 1967

In addition to Egypt, Syria acquired 38 SD-100s. These vehicles, like the Egyptian ones, were used in the 1967 Six Day War. Then the Israel Defense Forces pretty much replenished the collection of trophies. 100% of captured SU-100s in Israeli museums are SD-100s, which can be easily identified by their characteristic details.

The 1973 Yom Kippur War was the last in which the SD-100 fought en masse.

Later, deliveries of self-propelled guns from Czechoslovakia became mixed. In addition to the SD-100, a significant percentage were Soviet-made vehicles. Sometimes Czechoslovakia turned out to be only an intermediary between the USSR and other countries. For example, 50 SU-100s were delivered to Cuba from Czechoslovakia, but in fact these are Soviet vehicles. The situation is very similar with the 50th SU-100 that ended up in Yemen. The cars there are also clearly Soviet. Delivered SD-100 to Bulgaria, Romania, Ethiopia and Morocco.

Yuri Bakhurin

Czechoslovakian self-propelled guns in the Middle East

Photo review of the self-propelled guns SD-100 in the exposition of the Museum of the Israel Defense Forces

It's safe to say that the Czechoslovak military made the right choice with the SD-100. Although they did not succeed in producing tanks and self-propelled guns of their own design, they managed to solve the problem of arming the army with armored vehicles due to licensed production. In addition, thanks to the export deliveries of licensed cars, Czechoslovakia also managed to earn money. The country has again returned to the international arms market, albeit with combat vehicles not of its own design.

The author is grateful to Jiri Tintera and František Rozkot, Czech Republic, for their help in preparing the material.

Sources:

- Materials of VHU Prahan (Vojenský historický archive)

- Mgr.Martin Dubánek - Od bodáku po tryskáče - Nedokončené Československé zbrojní projekty 1945-1955, Mladá fronta 2011

- The Czechoslovak Army 1945–1954, Peter Brojo, Josef Studeny, Capricorn Publications, 2012, ISBN 978–80–87578–01–8.

- http://forum.valka.cz

- http://ftr.wot-news.com

- Photo archive of the author