Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

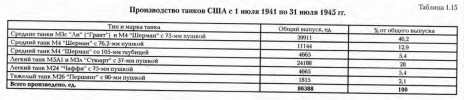

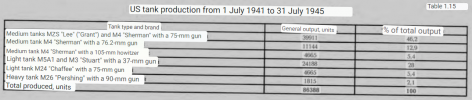

Neuvostoliiton ja Varsovan liiton (sekä muiden) tuotantomääristä

- Viestiketjun aloittaja Antares

- Aloitus PVM

Antares

Respected Leader

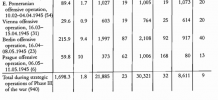

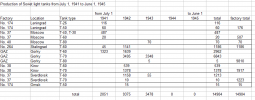

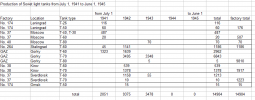

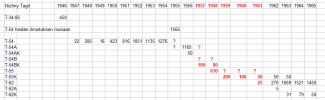

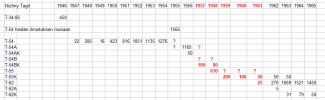

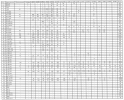

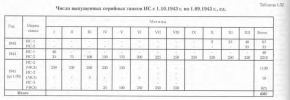

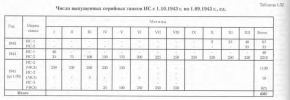

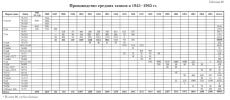

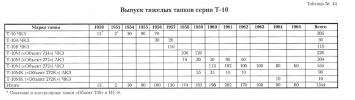

Neuvostoliiton eri vaunutyyppien valmistusmäärät vuosittain ennen toista maailmansotaa.

Lähde:

Отечественные бронированные машины. ХХ век. 1905-1941 - А.Г. Солянкин, М.В. Павлов, И.В. Павлов, И.Г. Желтов - 2002

Domestic armored vehicles. XX century. 1905-1941 - Solyankin A.G., Pavlov M.V., Pavlov I.V., Zheltov I.G. - 2002

Taulukko löytyy kirjan sivulta 17.

Huomaa, että tämän taulukon vuoden 1941 osuus on puolen vuoden osuus, ei koko vuosi. Käytännössä siis Saksan Neuvostoliittoon hyökkäämistä edeltäneen ajan tuotanto, päätepiste on 22.6.1941.

Supply of armored weapons and equipment by industrial plants in the Red Army

Note: * - Data are given for all serial tanks, including T-38M2;

** - Data are given for all serial flamethrower (chemical) tanks created on the basis of the T-26

Taulukon ensimmäisen datarivin nimen käännös: "Renault Russian". T-26 vaunun osalta on kaksi riviä, ylempi on "T-26 twin turret" ja sen alapuolella seuraava rivi on "T-26 single turret". Näiden alapuolella on rivi, jonka käännös on "T-26 from the mouth. P-40"

-

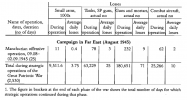

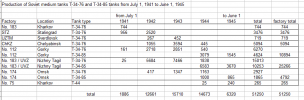

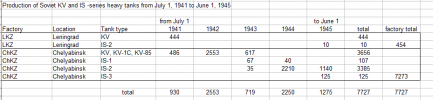

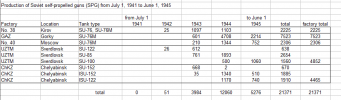

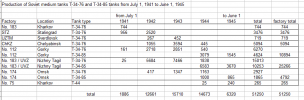

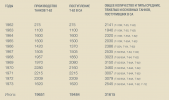

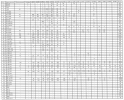

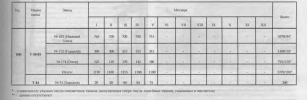

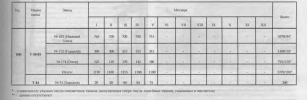

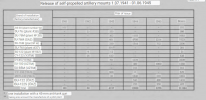

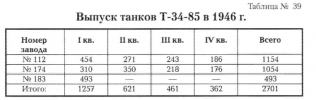

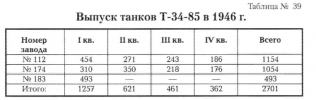

Neuvostoliiton eri vaunutyyppien valmistusmäärät vuosittain tehtaiden mukaan eriteltynä.

Lähde:

Отечественные бронированные машины. XX век. Том 2. 1941-1945 - А.Г. Солянкин, М.В. Павлов, И.В. Павлов, И.Г. Желтов - 2005

Domestic armored vehicles. XX century. Volume 2. 1941-1945 - Solyankin A.G., Pavlov M.V., Pavlov I.V., Zheltov I.G. - 2005

Taulukko löytyy kirjan sivulta 14.

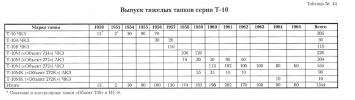

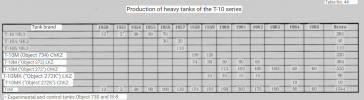

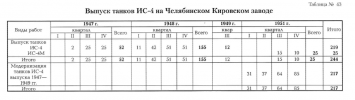

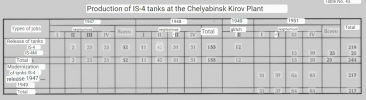

Production of Soviet tanks and self-propelled guns from July 1, 1941 to June 1, 1945

Note: Table 3 does not list 201 SU-76I and 21 SG-122 units manufactured in 1942-1943. Plants No. 37 and 592, respectively, based on captured tanks and self-propelled

guns, as well as 101 ZIS-30 installations manufactured in 1941 by Plant No. 92 on the basis of the domestic semi-armored tractor T-20 "Komsomolets".

-

Yllä olevan taulukon data, tässä se on kirjattu vaunutyypeittäin (pari kategoriaa sisältää useita vaunuja, koska niitä ei ole eritelty alkuperäisessä taulukossa tarkemmin enkä halunnut alkaa spekuloimaan). Huomaa, että aikaväli ei ole vuosien 1941-1945 tuotanto alusta loppuun vaan "from July 1, 1941 to June 1, 1945" - täten tästä taulukosta puuttuu 1941 vuoden tuotanto ennen Saksan hyökkäystä, mikä on puolen vuoden tuotanto ja sodan päättymistä seurannut 1945 vuoden tuotanto, joka on sekin käytännössä puolen vuoden tuotanto.

-

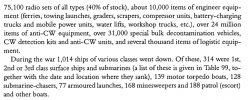

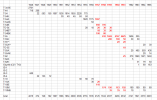

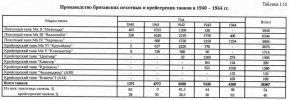

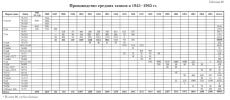

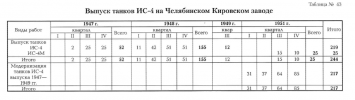

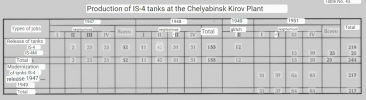

Neuvostoliiton eri vaunutyyppien valmistusmäärät vuosittain toisen maailmansodan jälkeen, aikaväli 1946-1965 sekä vuoden 1945 neljä viimeistä kuukautta.

Lähde:

Отечественные Бронированные Машины ХХ век Том 3: 1946-1965 - А.Г. Солянкин, И.Г. Желтов, К.Н. Кудряшов - 2010

Domestic armored vehicles. XX century. Volume 3. 1946-1965 - Solyankin A.G., Zheltov I.G., Kudryashov K.N. - 2010

Taulukko löytyy kirjan sivulta 20.

Huomaa, että taulukkoon merkitty vuoden 1945 määrä edustaa toisen maailmansodan jälkeistä tuotantoa, tässä se on merkitty syyskuusta joulukuuhun (IX-XII = 9-12). Täten tästä taulukosta puuttuu 1945 vuoden sodan aikana tehty tuotanto.

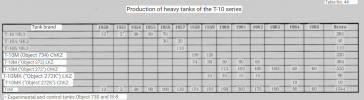

Production of tanks for the Soviet Army in the first post-war period (1946-1965)

* Of these, 96 are combat training.

** Tanks equipped for the installation of PST watercraft (tämän selitys: https://en.topwar.ru/8128-neobychnye-tanki-roscii-i-sssr-tanki-na-podvodnyh-krylyah.html)

-

Valitettavasti tämän erinomaisen kirjasarjan kolmas osa jäänee sen viimeiseksi, tietojeni mukaan kirjoittajaporukka hajosi sen jälkeen kuka minnekin eikä ole tarkoitusta kirjoittaa vuotta 1965 seuranneista kehityksistä. He ehtivät jo nimetä viimeisen kirjan:

"Отечественные бронированные машины. XX век. Том 4. 1966-2000" eli "Domestic armored vehicles. XX century. Volume 4. 1966-2000"

Heidän hyvin tarkka tyyli olisi varmasti tuonut lisävaloa kylmän sodan viimeisille vuosikymmenille sekä 90-luvun kaaokseen, harmi ettei tätä kirjaa tulla näkemään.

Lähde:

Отечественные бронированные машины. ХХ век. 1905-1941 - А.Г. Солянкин, М.В. Павлов, И.В. Павлов, И.Г. Желтов - 2002

Domestic armored vehicles. XX century. 1905-1941 - Solyankin A.G., Pavlov M.V., Pavlov I.V., Zheltov I.G. - 2002

Taulukko löytyy kirjan sivulta 17.

Huomaa, että tämän taulukon vuoden 1941 osuus on puolen vuoden osuus, ei koko vuosi. Käytännössä siis Saksan Neuvostoliittoon hyökkäämistä edeltäneen ajan tuotanto, päätepiste on 22.6.1941.

Supply of armored weapons and equipment by industrial plants in the Red Army

Note: * - Data are given for all serial tanks, including T-38M2;

** - Data are given for all serial flamethrower (chemical) tanks created on the basis of the T-26

Taulukon ensimmäisen datarivin nimen käännös: "Renault Russian". T-26 vaunun osalta on kaksi riviä, ylempi on "T-26 twin turret" ja sen alapuolella seuraava rivi on "T-26 single turret". Näiden alapuolella on rivi, jonka käännös on "T-26 from the mouth. P-40"

-

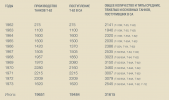

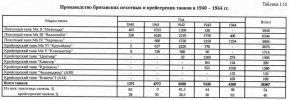

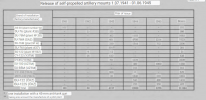

Neuvostoliiton eri vaunutyyppien valmistusmäärät vuosittain tehtaiden mukaan eriteltynä.

Lähde:

Отечественные бронированные машины. XX век. Том 2. 1941-1945 - А.Г. Солянкин, М.В. Павлов, И.В. Павлов, И.Г. Желтов - 2005

Domestic armored vehicles. XX century. Volume 2. 1941-1945 - Solyankin A.G., Pavlov M.V., Pavlov I.V., Zheltov I.G. - 2005

Taulukko löytyy kirjan sivulta 14.

Production of Soviet tanks and self-propelled guns from July 1, 1941 to June 1, 1945

Note: Table 3 does not list 201 SU-76I and 21 SG-122 units manufactured in 1942-1943. Plants No. 37 and 592, respectively, based on captured tanks and self-propelled

guns, as well as 101 ZIS-30 installations manufactured in 1941 by Plant No. 92 on the basis of the domestic semi-armored tractor T-20 "Komsomolets".

-

Yllä olevan taulukon data, tässä se on kirjattu vaunutyypeittäin (pari kategoriaa sisältää useita vaunuja, koska niitä ei ole eritelty alkuperäisessä taulukossa tarkemmin enkä halunnut alkaa spekuloimaan). Huomaa, että aikaväli ei ole vuosien 1941-1945 tuotanto alusta loppuun vaan "from July 1, 1941 to June 1, 1945" - täten tästä taulukosta puuttuu 1941 vuoden tuotanto ennen Saksan hyökkäystä, mikä on puolen vuoden tuotanto ja sodan päättymistä seurannut 1945 vuoden tuotanto, joka on sekin käytännössä puolen vuoden tuotanto.

-

Neuvostoliiton eri vaunutyyppien valmistusmäärät vuosittain toisen maailmansodan jälkeen, aikaväli 1946-1965 sekä vuoden 1945 neljä viimeistä kuukautta.

Lähde:

Отечественные Бронированные Машины ХХ век Том 3: 1946-1965 - А.Г. Солянкин, И.Г. Желтов, К.Н. Кудряшов - 2010

Domestic armored vehicles. XX century. Volume 3. 1946-1965 - Solyankin A.G., Zheltov I.G., Kudryashov K.N. - 2010

Taulukko löytyy kirjan sivulta 20.

Huomaa, että taulukkoon merkitty vuoden 1945 määrä edustaa toisen maailmansodan jälkeistä tuotantoa, tässä se on merkitty syyskuusta joulukuuhun (IX-XII = 9-12). Täten tästä taulukosta puuttuu 1945 vuoden sodan aikana tehty tuotanto.

Production of tanks for the Soviet Army in the first post-war period (1946-1965)

* Of these, 96 are combat training.

** Tanks equipped for the installation of PST watercraft (tämän selitys: https://en.topwar.ru/8128-neobychnye-tanki-roscii-i-sssr-tanki-na-podvodnyh-krylyah.html)

-

Valitettavasti tämän erinomaisen kirjasarjan kolmas osa jäänee sen viimeiseksi, tietojeni mukaan kirjoittajaporukka hajosi sen jälkeen kuka minnekin eikä ole tarkoitusta kirjoittaa vuotta 1965 seuranneista kehityksistä. He ehtivät jo nimetä viimeisen kirjan:

"Отечественные бронированные машины. XX век. Том 4. 1966-2000" eli "Domestic armored vehicles. XX century. Volume 4. 1966-2000"

Heidän hyvin tarkka tyyli olisi varmasti tuonut lisävaloa kylmän sodan viimeisille vuosikymmenille sekä 90-luvun kaaokseen, harmi ettei tätä kirjaa tulla näkemään.

Viimeksi muokattu:

Tässä eri vaunutyyppien valmistusmääriä sisältävä taulukko A.G. Solyankin, M.V. Pavlovin ja I.V. Pavlovin kirjasta nimeltä "Отечественные бронированные машины. ХХ век. 1905-1941"

Tuon nimen voi kääntää muotoon "Domestic armored vehicles. XX century. 1905-1941"

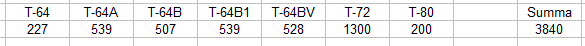

Käsittämättömiä numeroita. T-44 joka oli "vain" ylimenokauden tankki valmistettiin yli 1200 kpl.

Antares

Respected Leader

Antares

Respected Leader

T-64 vaunujen eri varianttien määristä, tämä lainaus on S. Suvorovin kirjasta "Танк Т-64 первенец танков второго поколения" (julkaistu vuonna 2001) sivut 56 ja 57. Otin sen käännöstyökalun läpi jotta testi on luettavissa (kirjasta löytyy myös skannattu versio täältä):

Huvittavasti hän moittii 90-luvun alkupuolen läntisiä kirjoituksia ja niiden virheitä, kun taas hänen kirjasta tunnistettuja virheitä on listattu mm. täällä: LINKKI

Yksi ikävimpiä on ettei kirja tarjoa luetteloa käytetyille lähteille, sikäli kun niitä on. Tämä on silti hyödyllinen, kirjoittaa mm. alkuperäisten T-64 vaunujen kohtalosta sekä antaa numeroita muutaman variantin tuotantomääristä:

T-64 = 600 - 1 700

T-64A = noin 4 600

T-64B = noin 4 200

T-64B1 = noin 1 200

T-64BK = 57

Näiden summa = 10 057 jos jätetään T-64 vaunut laskuista.

En sano että nämä Suvorovin kirjan määrät ovat välttämättä oikeat, mutta tarjoavat yhden datapisteen kokonaismääristä ja toisaalta jos törmäät internetissä näihin numeroihin, niin tiedät mistä ne tulevat.

Ukrainan wikipedian T-64 vaunua käsittelevä sivu sanoo että T-64AK valmistusmäärä olisi noin 780 kpl ja T-64BV osalta kirjoitetaan että niitä olisi Ukrainan armeijalla käytössä "more than 600". LÄHDE

Steve Zalogan mukaan: "In general, about 5 percent of Russian tanks were built in the command tank configuration". Jos näin on, niin T-64 vaunujen osalta 13 108 x 0,05 = 655 komentovaunua. En ole tarkastellut komentovaunujen määriä joten en osaa sanoa kuinka lähellä totuutta tuo on.

Alkuperäisten T-64 mallien eli Obyekt 432 valmistusmäärä on useamman lähteen mukaan 1 192 kpl

Steve Zaloga kirjoittaa kirjassaan "T-64 battle tank - the cold war's most secret tank" näiden vaunujen kohtalosta:

From 1977 to 1981, the T-64 tanks remaining in service underwent a capital rebuilding program that modernized their radio sets to current standards, added the Brod deep-wading system, and added a number of stowage features from the T-64A. These rebuilt T-64 tanks were designated as T-64R (R = remontniy; rebuilt).

Nizhny Tagilin tehtaan taulukon mukaan T-64A ja T-64B (sekä muut variantit) = 13 108 kpl

Zalogan kirja ei ota kantaa tuotantomääriin, tosin toteaa seuraavasti:

According to recent Russian accounts, total production of the T-64 was about 12,000 tanks, though details are lacking. The T-64A was frst deployed in the western military districts of the Soviet Union in the 1970s. The intention was to gradually deploy the T-64A with the frst-line units facing NATO in the GSFG in Germany and neighboring Warsaw Pact states. The frst unit given this task was the 14th Guards Mechanized Division in Juterborg in 1976, reorganized in 1982 as the 32nd Guards Tank Division. NATO frst spotted the arrival of the T-64A tank in East Germany in 1976. At frst, it was misidentifed as the T-72. The T-64A was deployed primarily with the Soviet tank units in the northern regions of East Germany with the 2nd Guards Tank Army, 3rd Shock Army, and 20th Guards Army. Its primacy in the GSFG was short-lived.

The new T-80A tank began arriving in Germany in April 1983, initially re-equipping the feld armies in the southern sectors of East Germany. However, before the withdrawal of the GSFG, the T-80 had begun to replace the T-64A and T-64B in the three northern feld armies as well. The T-64 remained in two divisions and one separate brigade in Germany at the time of the Soviet withdrawal. At the time of the collapse of the Soviet Union in 1991, there were 3,982 T-64 tanks in service west of the Urals, with 2,091 in Ukraine.The new Russian Army decided to standardize on the T-72 and T-80, and so the T-64 force was gradually put in reserve or scrapped. In 2014, the Russian force was estimated to number about 2,000 T-64 tanks in storage and there were additional tanks in the zone east of the Urals.

A number of other republics also ended up with modest numbers of T-64 tanks, including Kazakstan and Uzbekistan.

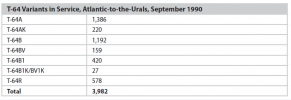

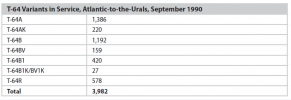

Kirja tarjoaa seuraavan taulukon eri varianttien määristä, mutta nämä ovat ainoastaan Neuvostoliiton ilmoittamat Uralin länsipuolelle sijoitetut vaunut vuonna 1990. Ei siis kerro mitään muuta tuon lisäksi, vaunuja oli sijoitettuna Uralin itäpuolelle eri varastoihin. Neuvostoliitto ei ollut hajonnut vuonna 1990 joten tässä on Venäjän ja Ukrainan määrät yhdessä.

Yhden lähteen mukaan Ukrainalle jääneet vaunut olivat, tosin CFE ilmoitusten perusteella T-80 vaunuja olisi ollut 350 kpl vuonna 1992. Tämän lisäksi alla olevasta taulukosta puuttuvat T-54 ja/tai T-55 vaunut, joita heillä oli myös "jokin määrä", arvatenkin useita satoja ellei jopa yli tuhat. Military Balancen mukaan heillä olisi ollut jo pitkään 112 kpl T-55 vaunuja, vanhin julkaisu jossa tämä mainitaan on vuodelta 2004 (vanhin julkaisu, johon minulla on pääsy):

Huvittavasti hän moittii 90-luvun alkupuolen läntisiä kirjoituksia ja niiden virheitä, kun taas hänen kirjasta tunnistettuja virheitä on listattu mm. täällä: LINKKI

Yksi ikävimpiä on ettei kirja tarjoa luetteloa käytetyille lähteille, sikäli kun niitä on. Tämä on silti hyödyllinen, kirjoittaa mm. alkuperäisten T-64 vaunujen kohtalosta sekä antaa numeroita muutaman variantin tuotantomääristä:

T-64 = 600 - 1 700

T-64A = noin 4 600

T-64B = noin 4 200

T-64B1 = noin 1 200

T-64BK = 57

Näiden summa = 10 057 jos jätetään T-64 vaunut laskuista.

En sano että nämä Suvorovin kirjan määrät ovat välttämättä oikeat, mutta tarjoavat yhden datapisteen kokonaismääristä ja toisaalta jos törmäät internetissä näihin numeroihin, niin tiedät mistä ne tulevat.

Ukrainan wikipedian T-64 vaunua käsittelevä sivu sanoo että T-64AK valmistusmäärä olisi noin 780 kpl ja T-64BV osalta kirjoitetaan että niitä olisi Ukrainan armeijalla käytössä "more than 600". LÄHDE

Steve Zalogan mukaan: "In general, about 5 percent of Russian tanks were built in the command tank configuration". Jos näin on, niin T-64 vaunujen osalta 13 108 x 0,05 = 655 komentovaunua. En ole tarkastellut komentovaunujen määriä joten en osaa sanoa kuinka lähellä totuutta tuo on.

Alkuperäisten T-64 mallien eli Obyekt 432 valmistusmäärä on useamman lähteen mukaan 1 192 kpl

Steve Zaloga kirjoittaa kirjassaan "T-64 battle tank - the cold war's most secret tank" näiden vaunujen kohtalosta:

From 1977 to 1981, the T-64 tanks remaining in service underwent a capital rebuilding program that modernized their radio sets to current standards, added the Brod deep-wading system, and added a number of stowage features from the T-64A. These rebuilt T-64 tanks were designated as T-64R (R = remontniy; rebuilt).

Nizhny Tagilin tehtaan taulukon mukaan T-64A ja T-64B (sekä muut variantit) = 13 108 kpl

Zalogan kirja ei ota kantaa tuotantomääriin, tosin toteaa seuraavasti:

According to recent Russian accounts, total production of the T-64 was about 12,000 tanks, though details are lacking. The T-64A was frst deployed in the western military districts of the Soviet Union in the 1970s. The intention was to gradually deploy the T-64A with the frst-line units facing NATO in the GSFG in Germany and neighboring Warsaw Pact states. The frst unit given this task was the 14th Guards Mechanized Division in Juterborg in 1976, reorganized in 1982 as the 32nd Guards Tank Division. NATO frst spotted the arrival of the T-64A tank in East Germany in 1976. At frst, it was misidentifed as the T-72. The T-64A was deployed primarily with the Soviet tank units in the northern regions of East Germany with the 2nd Guards Tank Army, 3rd Shock Army, and 20th Guards Army. Its primacy in the GSFG was short-lived.

The new T-80A tank began arriving in Germany in April 1983, initially re-equipping the feld armies in the southern sectors of East Germany. However, before the withdrawal of the GSFG, the T-80 had begun to replace the T-64A and T-64B in the three northern feld armies as well. The T-64 remained in two divisions and one separate brigade in Germany at the time of the Soviet withdrawal. At the time of the collapse of the Soviet Union in 1991, there were 3,982 T-64 tanks in service west of the Urals, with 2,091 in Ukraine.The new Russian Army decided to standardize on the T-72 and T-80, and so the T-64 force was gradually put in reserve or scrapped. In 2014, the Russian force was estimated to number about 2,000 T-64 tanks in storage and there were additional tanks in the zone east of the Urals.

A number of other republics also ended up with modest numbers of T-64 tanks, including Kazakstan and Uzbekistan.

Kirja tarjoaa seuraavan taulukon eri varianttien määristä, mutta nämä ovat ainoastaan Neuvostoliiton ilmoittamat Uralin länsipuolelle sijoitetut vaunut vuonna 1990. Ei siis kerro mitään muuta tuon lisäksi, vaunuja oli sijoitettuna Uralin itäpuolelle eri varastoihin. Neuvostoliitto ei ollut hajonnut vuonna 1990 joten tässä on Venäjän ja Ukrainan määrät yhdessä.

Yhden lähteen mukaan Ukrainalle jääneet vaunut olivat, tosin CFE ilmoitusten perusteella T-80 vaunuja olisi ollut 350 kpl vuonna 1992. Tämän lisäksi alla olevasta taulukosta puuttuvat T-54 ja/tai T-55 vaunut, joita heillä oli myös "jokin määrä", arvatenkin useita satoja ellei jopa yli tuhat. Military Balancen mukaan heillä olisi ollut jo pitkään 112 kpl T-55 vaunuja, vanhin julkaisu jossa tämä mainitaan on vuodelta 2004 (vanhin julkaisu, johon minulla on pääsy):

Viimeksi muokattu:

Antares

Respected Leader

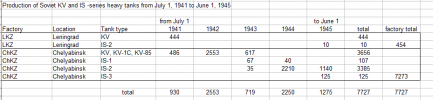

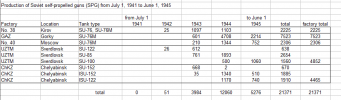

Yllä olevan viestin Neuvostoliiton toisen maailmansodan (from July 1, 1941 to June 1, 1945) sodanajan panssarivaunutuotanto pilkottuna vaunujen luokittelun mukaisesti:

Kevyet panssarivaunut (light tanks):

Keskiraskaat panssarivaunut (medium tanks):

Raskaat panssarivaunut (heavy tanks)

Rynnäkkötykit (self-propelled guns):

-

Alla koko taulukko yhdessä, tosin jos vertaa Solyankin et. al. kirjan taulukkoon niin rivien järjestys on hieman eri (sisältö on tietysti sama).

Tässä minun taulukossa tehtaat on järjestetty länsi-itä -suunnassa karkeasti, näkee helpommin tehtaiden tuotannon hiipumisen Saksan hyökkäyksen edetessä ja toisaalta tuotantolinjojen uudelleenkäynnistämisen kun hyökkäys pysähtyi ja vaihtoi suuntaa:

Kevyet panssarivaunut (light tanks):

Keskiraskaat panssarivaunut (medium tanks):

Raskaat panssarivaunut (heavy tanks)

Rynnäkkötykit (self-propelled guns):

-

Alla koko taulukko yhdessä, tosin jos vertaa Solyankin et. al. kirjan taulukkoon niin rivien järjestys on hieman eri (sisältö on tietysti sama).

Tässä minun taulukossa tehtaat on järjestetty länsi-itä -suunnassa karkeasti, näkee helpommin tehtaiden tuotannon hiipumisen Saksan hyökkäyksen edetessä ja toisaalta tuotantolinjojen uudelleenkäynnistämisen kun hyökkäys pysähtyi ja vaihtoi suuntaa:

Viimeksi muokattu:

Antares

Respected Leader

Tuumailua T-80 vaunujen valmistusmääristä sekä tuotannon eri vaiheista, seuraavat lainaukset ovat Steve Zalogan kirjasta "T-80 standard tank - Soviet armys last champion" (kirja julkaistu 17.2.2009):

-

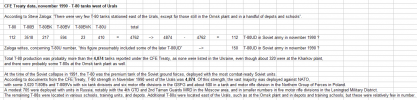

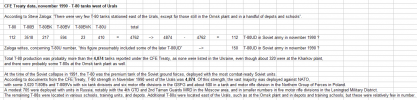

In its original configuration, the long-delayed T-80 was essentially identical to the older T-64A in firepower, as it used exactly the same type of turret with an optical rangefinder. But it was hideously expensive: R480,000 versus R143,000 for the T-64A. In respect to its turret and fire controls, it was already behind the Kharkov T-64, which had evolved by 1976 into the T-64B with a new fire-control system incorporating a laser rangefinder and the capability to fire the Kobra tube-launched guided missile. As a result, production of the T-80 was very short-lived, running from only 1976 to 1978 at LKZ. Data released under the Conventional Forces in Europe (CFE) Treaty from November 1990, indicated that there were only 112 T-80s west of the Urals, which suggests that overall T-80 production was probably well under 200 tanks.

-

The Obiekt 219R was accepted for Soviet service in 1978 as the T-80B and entered production at LKZ that year, replacing the earlier T-80. It entered production at the Omsk plant in 1979, belatedly replacing the T-55A that was still in production there for export. The Omsk plant was also assigned to develop the Obiekt 630 command version of the T-80B, designated T-80BK. The command version added a land navigation system and an additional command radio.

The T-80B became the most common production version of the T-80, and the first version to be forward deployed with the Group of Soviet Forces in Germany (GSFG) starting in 1981. The T-80B was first seen by NATO moving into Germany in April 1983 near Halle, beginning with the 29th Tank Regiment, 9th Tank Division of the 1st Guards Tank Army (GTA), and with units of the 8th GTA in 1984. By 1985, each division in the 1st GTA and 8th GTA had received some T-80B tanks. According to data released under the CFE Treaty, there were 3,518 T-80B and 217 T-80BK command tanks in service west of the Urals in November 1990, plus a further 617 upgraded T-80BV, for a grand-total of 4,352, amounting to 90 percent of overall T-80 strength. There were very few T-80 tanks stationed east of the Urals, except for those still in the Omsk plant and in a handful of depots and schools.

-

Kontakt began to be fitted to Soviet tanks in 1983 and was first deployed with the GSFG in 1984. In 1985, the LKZ began to manufacture the T-80B with Kontakt as T-80BV (Obiekt 219RV); the corresponding command tank version was T-80BVK. The "V" suffix added to the designations indicated "explosive" (vyzryvnoi). During periodic rebuilding, older tanks were retrofitted with the Kontakt package. According to CFE Treaty documents, in November 1990 there were 594 T-80BV and 23 T-80BVK command tanks in Soviet service west of the Urals, amounting to about 13 percent of T-80 tank strength.

-

With the retirement of Aleksandr Morozov, the chief designer at the Kharkov plant in May 1976, defense minister Ustinov attempted to impose a greater degree of standardization on Soviet tank designs. Kharkov had been developing an improved T-64B with substantially improved fire controls and new turret armor as the Obiekt 476 or Izdeliye 9A. Rather than waste time transferring the features to a new T-80 turret, Moscow decided to merge the new Kharkov turret with the T-80B hull the Obiekt 219A Olkha, and then to shift Kharkov's production from the T-64B to the T-80. Under this scheme, Popov's design bureau at LKZ was responsible for the overall program while Kharkov's new chief designer, Nikolai Shomin, was responsible for the turret and armament. The Obiekt 476 turret included a new generation of laminate armor and the improved lA45 fire-control system with the new IG46 sight.

At the time, two different types of advanced composite turret armor were being examined by NIl Stali, and their reflecting-plate armor (bronya s otrazhayushchimi listami) was adopted on the new T-72B. The cavity in the front of the cast steel turret was filled with a laminate of alternating metal and non-metallic plates. The Obeikt 476 used a more expensive, semi-active filledcell armor (bronya s yachestim napolnitelem) in the cavity consisting of two rows of polymer-filled cells backed by a steel plate and another layer of resin. When the cells were penetrated by the shaped-charge jet, shock waves reverberated in the semi-liquid filler in the cells, degrading the penetrator. Although the Obiekt 219A was ready for production at Kharkov in the 1982 time-frame, production was limited to a relatively small number of tanks for trials purposes due to the other ongoing technology initiatives, including tubefired missiles and reactive armor.

-

As mentioned earlier, the Soviet Army pushed Kontakt-1 into service almost immediately. Kontakt was not entirely popular with the Soviet tank designers as it added 1.2 metric tons to the weight of the tank and was only able to protect against shaped charge warheads. By the mid-1980s, NATO was shifting its tactics towards the use of armor-piercing, fin-stabilized, discarding-sabot (APFSDS) projectiles for tank guns, which were not affected by Kontakt. The Soviet Army acquired some examples of Israeli MIll APFSDS 105mm ammunition from the Syrians that had been captured in the 1982 Lebanon war. Tests of this ammunition in the Soviet Union in 1982-83 indicated it could penetrate the existing glacis ~rmor of tanks such as the T-72 and T-80. As a short-term fix, 20mm steel armor applique was applied to T-80B glacis plates. In addition, NIl Stali accelerated research on a secondgeneration "universal" ERA called Kontakt-5, which was intended to have some capability to degrade APFSDS projectiles as well as shaped-charge warheads. Kontakt-5 relied on a much more substantial steel plate on the outside of the panel and this material was sufficient both to increase the degradation of shaped-charge jets, and also degrade APFSDS penetration by about 20-35 percent. This plate required a more energetic explosive insert, with a TNT equivalent of 0.28kg in the 4S20 panels of Kontakt-1 versus 0.33kg in the 4S22 panels of the Kontakt-5. The Kontakt-5 panels had to be properly angled for maximum effect and in combination with their size and weight, they could not be bolted on, as had been the case with Kontakt1. Kontakt-5 had to be incorporated as a comprehensively designed armor package that would have to be undertaken during original manufacture or during capital rebuilding. As a result, Kontakt-1 and Kontakt-5 were distinguished from one another as applique ERA (navesnoy DZ) versus integrated ERA (vstroenniy DZ).

The new Obiekt 219AS merged the features of Obiekt 219A and Obiekt 219V along with the Kontakt-5 protective package. A pre-production batch of 20 Obiekt 219AS was completed in late 1983, with eight immediately sent for troop trials and the remainder for state trials and factory testing. The Obiekt 219AS was accepted for Soviet Army service in 1985 as the T-80U (U = usovershenstvovanniy: improved) and went into series production at Omsk in 1987. According to documents released under the CFE Treaty, there were 410 T-80U tanks in operational service west of the Urals in November 1990, or about 8 percent of T-80 strength; this figure presumably included some of the later T-80UD (see below).

-

The shortcomings of the turbine engine in the T-80 led to a continuing string of experimental alternatives using diesel propulsion. An initial diesel-powered version was developed by LKZ beginning in 1975-1976, powered by the 2V16 (A-53-2) 1,000hp diesel designed by the Transdizel Special Design Bureau at the Chelyabinsk Motor Plant. This was mounted on a modified T-80B chassis as the Obiekt 219RD, but was not ready until 1983. Another diesel test-bed was developed at Omsk as the Obiekt 644, using the V-46-6 of the T-72 tank. Neither of these reached the production stage due to Ustinov's "turbinization" program. Nevertheless, there was continuing interest in the Soviet Army to replace the turbine on the T-80 due to its high procurement and operating costs. For example, in the 1980s the V-46 diesel engine on the T-72 cost only R9,600 while the GTD-1 000 turbine was more than ten times more expensive at R104,000. Furthermore, the turbine had a shorter running life, consumed more fuel, and was complicated and expensive to maintain and repair.

Even if Ustinov insisted that Kharkov shift from T-64 to T-80 production, the Kharkov plant wanted to build their T-80s with a diesel. So the Obiekt 478, a third effort to develop a diesel-powered T-80, started in 1976 at Kharkov. It used the new 6TD 1,000 hp diesel developed at Kharkov for the improved T-64 (Obiekt 476) and the next-generation T-74. Another option was also explored, the Obiekt 478M, which was a much more elaborate configuration with the new Sistema fire-control system, Shater active protection system, and a Chelyabinsk Transdizel X-layout 1,500hp 124Ch diesel. The Obiekt 478M was recognized as being a case of the" best being the enemy of the good" - it was simply too expensive and complicated. The Obiekt 478, on the other hand, was falling behind the contemporary Obiekt 476 upgrade in terms of fire controls and armament features; for example, it relied on the older Kobra missile instead of the newer Refleks being considered for Obiekt 476. Nevertheless, Ustinov was still insistent on the "turbinization" of the army, and so production of the T-64B at Kharkov ended and the facility began to re-tool to manufacture the T-80U.

Ustinov's views were not universally shared within the Soviet Army and a Defense Ministry study in 1984 concluded that for the next five-year plan, the Soviet Army could purchase 2,500 tanks and 6,000 6TD diesel engines, or 1,500 tanks and 2,000 GTD-1250 turbine engines. Ustinov's death in December 1984, followed by that of Leningrad party-boss Romanov in July 1985, removed the two most prominent supporters of the Leningrad turbine tank and cleared the way for a return to diesel tanks. Production of the T-80U at Kharkov had been painfully slow anyway, and in the event only 45 were built there. Government approval for a diesel powered T-80U was speedily granted on September 2, 1985.

The Obiekt 478 diesel program was restarted as Obiekt 478B Bereza (Birch tree) with the 6TD engine in the T-80U. A total of five prototypes were quickly completed by year's end for trials purposes, but a parallel set of prototypes based on the less elaborate Obiekt 219A with the diesel were also built for comparison. Due to the earlier studies, test and evaluation work was very quickly completed and as a result, Obiekt 478B Bereza was demonstrated at the Kharkov tank school to Mikhail Gorbachev and other senior government and army officials. Government approval for production was quickly granted in 1986 but the production program was far from trouble-free, and the Soviet Army demanded improvements before large-scale production began. The original plan had been to designate the diesel-powered T-80U as the T-84, following the Kharkov tradition of the T-34, T-44, T-54, T-64 and T-74. This proposal led to a bitter "fight under the carpet" between the industry and army, with some detractors noting that the T-84 designation would draw attention to the fact that the Soviet Army was operating four different "standard" tanks - T-64, T-72, T-80, and T-84 - all with essentially the same characteristics except for four different powerplants. The issue was so contentious that it went to the top - Gorbachev's Central Committee of the Communist Party - for a final decision. In the end, the less conspicuous designation T-80UD was selected, indicating "Improved Diesel" (Usovershenstvovanniy Dieselniy). Soviet tank production continued to decline in the late 1980s due to Gorbachev's attempts to rein in defense spending. The original 1989 plan had been for 3,739 T-80 and T-72 tanks, but this was cut back to 1,530 tanks, and the 1990 plan cut to 1,445 tanks.

Total production of the T-80UD prior to the Soviet collapse was rather modest at about 500 tanks, of which about 350 were still located at the Kharkov plant when the Soviet Union collapsed in 1991 (huom. Neuvostoliitto hajosi virallisesti 26 joulukuuta 1991 joten sinänsä oletan että tuon vuoden tuotanto valmistui kokonaisuudessaan, paitsi jos oli jotain aikataulusta myöhäisiä vaunuja sekä tuotantolinjalla tietysti keskeneräisiä eri vaiheissa kokoonpanoa). The T-80UD was first deployed with the two "Kremlin court divisions": the 4th Guards Kantemirovskaya Tank Division (4th GTD) and the 2nd Guards Taman Motor Rifle Division (MRD) in the Moscow area. The T-80UD was first publicly shown at the May 9, 1990 Victory Day parade in Red Square in Moscow. They were seen on the Moscow streets again during the attempted putsch in August 1991.

-

At the time of the Soviet collapse in 1991, the T-80 was the premium tank of the Soviet ground forces, deployed with the most combat-ready Soviet units. According to documents from the CFE Treaty, T-80 strength in November 1990 west of the Urals was 4,874. Of this strength, the vast majority was deployed against NATO, with some 3,020 T-80Bs and T-80BVs with six tank divisions and six motor rifle divisions in the GSFG and about 600 in a tank and motor rifle division in the Northern Group of Forces in Poland. A modest 705 were deployed with units in Russia, notably with the 4th GTD and 2nd Taman Guards MRD in the Moscow area, and in smaller numbers in five motor rifle divisions in the Leningrad Military District. The remaining T-80s were located in various schools, training units, and depots. Additional T-80s were located east of the Urals, such as at the Omsk plant and in depots and training schools, but these were relatively few in number. Total T-80 production was probably more than the 4,874 tanks reported under the CFE Treaty, as none were listed in the Ukraine, even though about 320 were at the Kharkov plant, and there were probably some T-80s at the Omsk tank plant as well.

As a result of the Soviet collapse, nearly all of the T-80 tanks were in Russian control except for about 350 tanks, mainly T-80UD, located in Ukraine at the Kharkov plant and less than a hundred in Belarus. The tanks stationed in German and Poland were gradually repatriated back to Russia through the mid-1990s. The collapse of the Soviet Union threw the Soviet tank industry into crisis. At the time, only three of the five assembly plants were still active. Nizhni-Tagil was manufacturing the T-72B, Kharkov was manufacturing the T-80UD, and Omsk was manufacturing the T-80U; Leningrad and Chelyabinsk were no longer very active in tank assembly. Kharkov is located in Ukraine, and so was split off from the other Soviet plants in Russia. The political turmoil was accompanied by a precipitous decline in defense funding and virtually no new tanks were funded in Russia from 1991 to about 2005, although some production continued based on existing contracts and parts.

-

Once again, the fate of the Russian tank program was determined by politics more than technology. Having been the past victim of Kremlin politics, the Uralvagon plant proved to have learned its lesson. To avoid the taint of the Chechen war, the new T-72BU version of the T-72 tank was renamed the "T-90." Eduard Rossel, the governor of the Sverdlovsk region where the Nizhni-Tagil plant was located, vigorously campaigned for the T-90 as the future Russian tank. In 1996, the Russian Army announced that the T-90 would be the preferred tank for the immediate future. The decision made little difference in the short run, as there was no procurement funding for either the T-80U or T-90 for almost a decade. In the event, the T-90 prospered, as the Uralvagon plant at Nizhni-Tagil had an extensive commercial business in railroad equipment that kept the factory alive until state orders for tanks resumed in 2005. In addition, Nizhni-Tagil had better success in the export market, winning some large T-72 and T-90 sales to India and several other countries. In contrast, Omsk had a very difficult time winning export orders. The T-80U was significantly more expensive to purchase and operate than the T-72, and the Russian Army decision in favor of the T-90 did not help the T-80's export prospects. In addition, it faced competition from the Ukrainian Kharkov tank plant, which was offering the T-80UD/T-84 on the export market. Whether the T-90 was favored or not, by the late 1990s the T-80 was the backbone of Russian tank forces. Older tanks had been retired due to a lack of funds and of the 5,546 tanks still in service west of the Urals in 1997, 3,210 were T-80 tanks, almost 60 percent.

-

A handful of export orders for the T-80U did materialize, though they were fulfilled mostly by using undelivered inventory from the Omsk plant. Morocco acquired about five T-80 tanks in the late 1980s, ostensibly for testing for a future tank requirement; it is widely believed that they ended up in the hands of US, British, and German intelligence agencies. Russia sold Britain one T-80U in 1992 as a goodwill gesture connected with President Boris Yeltsin's visit to Britain in 1992. Sweden evaluated the T-80U for its tank competition starting in 1993, but finally settled on the Leopard 2. The Russian government owed South Korea a substantial amount of money from the Soviet period, and partly paid these debts through the sale of military equipment. The Republic of Korea Army received about 80 T-80U tanks from 1996 to 2005. These are used primarily by "opposing forces" units for training. Cyprus acquired 41 T-80U tanks, including 14 of the new T-80UK command tanks in 1996-97.

Omsk attempted to reinvigorate international interest in the T-80 by more elaborate improvements, including active protection systems as detailed below. Export sales were too small to keep the Omsk tank plant busy, and in spite of a few small state orders for tank rebuilding, the plant went bankrupt in 2006. At the time of writing (huom. kirja julkaistu 17.2.2009 joten "kirjoitushetki" on jotain tuota ennen, ehkä vuoden 2008 loppu), the Russian government planned to consolidate the tank business around Uralvagon in Nizhni-Tagil, with Omsk assigned tank rebuilding efforts as well as some design work. The Russian Army began to fund upgrades for its aging T-80 fleet in the 2007 defense budget.

-

The Kharkov plant in newly independent Ukraine attempted to keep T-80 production alive there, but suffered from some unique problems. About 70 percent of the T-80UD came from plants outside Ukraine, mainly Russia. Production was 800 combat vehicles in 1991, but only 43 in 1992 and none in 1993 as the supply of components dried up. Since the Ukrainian state budget was too small to support any extensive production, the plant turned to the export market. In 1993, the Malyshev plant demonstrated the T-80UD to Pakistan and in the summer of 1995, two T-80UD underwent extensive testing there. In August 1996, Pakistan announced plans to purchase 320 T-80UD tanks from Ukraine. One critical component was the cast turret - this came from the Azvostal foundry in Mariupol, which had already ceased production; the other casting facility was at the Omsk plant in Russia. So the Malyshev plant's design bureau developed a new welded turret that resulted in the Obiekt 478BK (BK = Bereza-Katanaya: Rolled-armor birch tree), with the first completed in 1993. Ukraine began manufacturing its own version of the D-81 125mm gun at the KBA-3. Of the 320 tanks delivered to Pakistan in 1997-1999, 145 used the original cast turret, including 52 tanks completed under Soviet contracts but never delivered, plus new tanks built with remaining Soviet-era turrets, and some tanks from Ukrainian army stocks. Ukrainian Army T-80 strength fell from about 350 tanks prior to the sale to 271 afterwards. The remaining 175 tanks were the new production Obiekt 478BE with the welded turret.

-

Although the Ukrainian government made repeated promises to begin purchasing the T-84 tank for the Ukrainian Army, the budget was too small to do so. A total of ten T-84M were ordered and delivered in 2002-2003. However, the government had problems paying for all the tanks, and four were sold off to the United States in 2003. A lack of orders from the Ukrainian government or from export clients left the Kharkov plant in grave economic straits and restricted their development efforts after 2005.

-

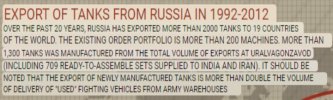

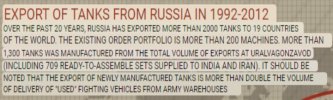

Tämä lainaus on Zalogan kirjasta "T-90 standard tank: the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivuilta 4-6 ja tarjoaa lisätietoa panssarivaunujen tuotantomäärille 90-luvun alussa:

-

The imposition of the “defense sufficiency” doctrine in the Gorbachev years led to substantial reductions in Soviet tank production. The Soviet Union had five tank plants in 1980 but only three remained active by 1991. After the Soviet collapse, only two remained inside the Russian Federation. Annual tank production plummeted from 3,254 in 1987 to 1,000 in 1991 and fell rapidly after that. The Kharkov tank plant, long considered the premier Soviet tank design and production center, had produced 800 T-80UD tanks in 1991. Since it was located in Ukraine, the Kharkov plant was cut off from the Russian Federation. T-80U production in St Petersburg at the Leningrad Kirov Plant ceased in 1990 prior to the Soviet collapse. T-72 production at the Chelyabinsk Tractor Plant (ChTZ) had ceased in 1989 after 1,522 had been built there. This left only two functioning tank plants in Russia, the Uralvagonzavod (UVZ: Ural Rail-Car Plant) in Nizhni-Tagil and the Transmash plant in Omsk in Siberia. Of these two, the UVZ in Nizhni-Tagil was the more significant. It included both a substantial design bureau, nicknamed the “Vagonka,” as well as a large manufacturing facility. It had been responsible for the design of several Soviet tanks during the Cold War years including the T-55, T-62 and T-72. The Omsk plant had a very small design staff and was regarded as a subsidiary plant, usually manufacturing tanks developed at other locations. At the time of the Soviet collapse, the T-80U was still in production at the Transmash Plant in Omsk while T-72 was in production at UVZ in Nizhni-Tagil.

In 1992, the Russian defense ministry made it clear that it could no longer afford to simultaneously buy two main battle tanks. Russian officials stated that they wished to cut production down to a single type, either the T-72 or the T-80. However, selecting one or the other tank meant that economic catastrophe would befall the losing city. Therefore, Russian officials continued to order both types in small amounts. In 1992, the Russian Army ordered only 20 tanks: 5 T-80U tanks from Omsk and 15 tanks from Nizhni-Tagil. Tank production at Omsk and Nizhni-Tagil in 1992–93 was well beyond the puny state orders due to some export orders, but only a pale shadow of the 1980s. This additional production was not ordered by the Russian Army, but undertaken simply to keep the plants from closing. There was the hope that large export orders would emerge to save the plants and sop up this surplus. However the anticipated export orders did not materialize. The UVZ in Nizhni-Tagil had about 350 T-72S and T-90 tanks in its factory yards, and Omsk had 150−200 T-80U tanks. Some of these T-80U tanks were exported to Cyprus and South Korea in 1996; UVZ gradually exported the T-72 tanks. Lack of pay at the Nizhni-Tagil plant led to strikes in July 1995 during which the workers seized several of the idle tanks and drove them through the city in protest.

-

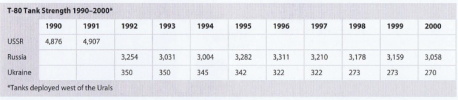

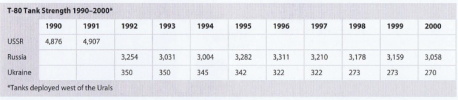

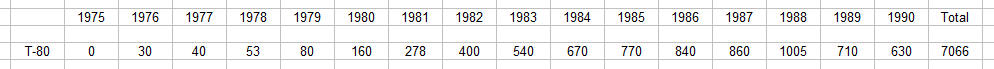

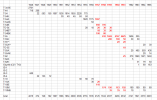

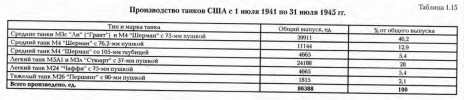

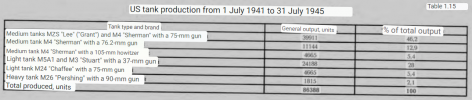

Taulukko Steve Zalogan kirjasta "T-80 standard tank - Soviet armys last champion" (kirja julkaistu 17.2.2009) sivulta 34:

Tämä taulukko on Zalogan kirjasta "T-90 standard tank - the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivulta 10. Huomaa, että vuoden 1991 numerot koskevat Neuvostoliittoa, mutta 1992 on pelkästään Venäjä. Siitä puuttuu siis Ukrainan ja Valko-Venäjän omistukseen siirtyneet vaunut, ehkä myös osa on siirretty Uralin itäpuolelle:

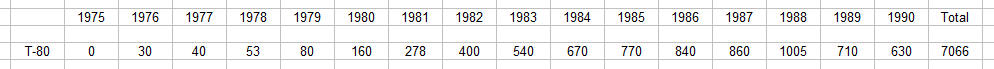

Tässä ovat T-80 vuosittaiset valmistusmäärät kuten ne on kerrottu siinä Nizhny Tagilin taulukossa (johon Zaloga viittaa omassa taulukossaan kirjassa "T-90 standard tank: the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivulla 5):

Zalogan kirjoittaman perusteella jako vaunutyypeittäin:

-

In its original configuration, the long-delayed T-80 was essentially identical to the older T-64A in firepower, as it used exactly the same type of turret with an optical rangefinder. But it was hideously expensive: R480,000 versus R143,000 for the T-64A. In respect to its turret and fire controls, it was already behind the Kharkov T-64, which had evolved by 1976 into the T-64B with a new fire-control system incorporating a laser rangefinder and the capability to fire the Kobra tube-launched guided missile. As a result, production of the T-80 was very short-lived, running from only 1976 to 1978 at LKZ. Data released under the Conventional Forces in Europe (CFE) Treaty from November 1990, indicated that there were only 112 T-80s west of the Urals, which suggests that overall T-80 production was probably well under 200 tanks.

-

The Obiekt 219R was accepted for Soviet service in 1978 as the T-80B and entered production at LKZ that year, replacing the earlier T-80. It entered production at the Omsk plant in 1979, belatedly replacing the T-55A that was still in production there for export. The Omsk plant was also assigned to develop the Obiekt 630 command version of the T-80B, designated T-80BK. The command version added a land navigation system and an additional command radio.

The T-80B became the most common production version of the T-80, and the first version to be forward deployed with the Group of Soviet Forces in Germany (GSFG) starting in 1981. The T-80B was first seen by NATO moving into Germany in April 1983 near Halle, beginning with the 29th Tank Regiment, 9th Tank Division of the 1st Guards Tank Army (GTA), and with units of the 8th GTA in 1984. By 1985, each division in the 1st GTA and 8th GTA had received some T-80B tanks. According to data released under the CFE Treaty, there were 3,518 T-80B and 217 T-80BK command tanks in service west of the Urals in November 1990, plus a further 617 upgraded T-80BV, for a grand-total of 4,352, amounting to 90 percent of overall T-80 strength. There were very few T-80 tanks stationed east of the Urals, except for those still in the Omsk plant and in a handful of depots and schools.

-

Kontakt began to be fitted to Soviet tanks in 1983 and was first deployed with the GSFG in 1984. In 1985, the LKZ began to manufacture the T-80B with Kontakt as T-80BV (Obiekt 219RV); the corresponding command tank version was T-80BVK. The "V" suffix added to the designations indicated "explosive" (vyzryvnoi). During periodic rebuilding, older tanks were retrofitted with the Kontakt package. According to CFE Treaty documents, in November 1990 there were 594 T-80BV and 23 T-80BVK command tanks in Soviet service west of the Urals, amounting to about 13 percent of T-80 tank strength.

-

With the retirement of Aleksandr Morozov, the chief designer at the Kharkov plant in May 1976, defense minister Ustinov attempted to impose a greater degree of standardization on Soviet tank designs. Kharkov had been developing an improved T-64B with substantially improved fire controls and new turret armor as the Obiekt 476 or Izdeliye 9A. Rather than waste time transferring the features to a new T-80 turret, Moscow decided to merge the new Kharkov turret with the T-80B hull the Obiekt 219A Olkha, and then to shift Kharkov's production from the T-64B to the T-80. Under this scheme, Popov's design bureau at LKZ was responsible for the overall program while Kharkov's new chief designer, Nikolai Shomin, was responsible for the turret and armament. The Obiekt 476 turret included a new generation of laminate armor and the improved lA45 fire-control system with the new IG46 sight.

At the time, two different types of advanced composite turret armor were being examined by NIl Stali, and their reflecting-plate armor (bronya s otrazhayushchimi listami) was adopted on the new T-72B. The cavity in the front of the cast steel turret was filled with a laminate of alternating metal and non-metallic plates. The Obeikt 476 used a more expensive, semi-active filledcell armor (bronya s yachestim napolnitelem) in the cavity consisting of two rows of polymer-filled cells backed by a steel plate and another layer of resin. When the cells were penetrated by the shaped-charge jet, shock waves reverberated in the semi-liquid filler in the cells, degrading the penetrator. Although the Obiekt 219A was ready for production at Kharkov in the 1982 time-frame, production was limited to a relatively small number of tanks for trials purposes due to the other ongoing technology initiatives, including tubefired missiles and reactive armor.

-

As mentioned earlier, the Soviet Army pushed Kontakt-1 into service almost immediately. Kontakt was not entirely popular with the Soviet tank designers as it added 1.2 metric tons to the weight of the tank and was only able to protect against shaped charge warheads. By the mid-1980s, NATO was shifting its tactics towards the use of armor-piercing, fin-stabilized, discarding-sabot (APFSDS) projectiles for tank guns, which were not affected by Kontakt. The Soviet Army acquired some examples of Israeli MIll APFSDS 105mm ammunition from the Syrians that had been captured in the 1982 Lebanon war. Tests of this ammunition in the Soviet Union in 1982-83 indicated it could penetrate the existing glacis ~rmor of tanks such as the T-72 and T-80. As a short-term fix, 20mm steel armor applique was applied to T-80B glacis plates. In addition, NIl Stali accelerated research on a secondgeneration "universal" ERA called Kontakt-5, which was intended to have some capability to degrade APFSDS projectiles as well as shaped-charge warheads. Kontakt-5 relied on a much more substantial steel plate on the outside of the panel and this material was sufficient both to increase the degradation of shaped-charge jets, and also degrade APFSDS penetration by about 20-35 percent. This plate required a more energetic explosive insert, with a TNT equivalent of 0.28kg in the 4S20 panels of Kontakt-1 versus 0.33kg in the 4S22 panels of the Kontakt-5. The Kontakt-5 panels had to be properly angled for maximum effect and in combination with their size and weight, they could not be bolted on, as had been the case with Kontakt1. Kontakt-5 had to be incorporated as a comprehensively designed armor package that would have to be undertaken during original manufacture or during capital rebuilding. As a result, Kontakt-1 and Kontakt-5 were distinguished from one another as applique ERA (navesnoy DZ) versus integrated ERA (vstroenniy DZ).

The new Obiekt 219AS merged the features of Obiekt 219A and Obiekt 219V along with the Kontakt-5 protective package. A pre-production batch of 20 Obiekt 219AS was completed in late 1983, with eight immediately sent for troop trials and the remainder for state trials and factory testing. The Obiekt 219AS was accepted for Soviet Army service in 1985 as the T-80U (U = usovershenstvovanniy: improved) and went into series production at Omsk in 1987. According to documents released under the CFE Treaty, there were 410 T-80U tanks in operational service west of the Urals in November 1990, or about 8 percent of T-80 strength; this figure presumably included some of the later T-80UD (see below).

-

The shortcomings of the turbine engine in the T-80 led to a continuing string of experimental alternatives using diesel propulsion. An initial diesel-powered version was developed by LKZ beginning in 1975-1976, powered by the 2V16 (A-53-2) 1,000hp diesel designed by the Transdizel Special Design Bureau at the Chelyabinsk Motor Plant. This was mounted on a modified T-80B chassis as the Obiekt 219RD, but was not ready until 1983. Another diesel test-bed was developed at Omsk as the Obiekt 644, using the V-46-6 of the T-72 tank. Neither of these reached the production stage due to Ustinov's "turbinization" program. Nevertheless, there was continuing interest in the Soviet Army to replace the turbine on the T-80 due to its high procurement and operating costs. For example, in the 1980s the V-46 diesel engine on the T-72 cost only R9,600 while the GTD-1 000 turbine was more than ten times more expensive at R104,000. Furthermore, the turbine had a shorter running life, consumed more fuel, and was complicated and expensive to maintain and repair.

Even if Ustinov insisted that Kharkov shift from T-64 to T-80 production, the Kharkov plant wanted to build their T-80s with a diesel. So the Obiekt 478, a third effort to develop a diesel-powered T-80, started in 1976 at Kharkov. It used the new 6TD 1,000 hp diesel developed at Kharkov for the improved T-64 (Obiekt 476) and the next-generation T-74. Another option was also explored, the Obiekt 478M, which was a much more elaborate configuration with the new Sistema fire-control system, Shater active protection system, and a Chelyabinsk Transdizel X-layout 1,500hp 124Ch diesel. The Obiekt 478M was recognized as being a case of the" best being the enemy of the good" - it was simply too expensive and complicated. The Obiekt 478, on the other hand, was falling behind the contemporary Obiekt 476 upgrade in terms of fire controls and armament features; for example, it relied on the older Kobra missile instead of the newer Refleks being considered for Obiekt 476. Nevertheless, Ustinov was still insistent on the "turbinization" of the army, and so production of the T-64B at Kharkov ended and the facility began to re-tool to manufacture the T-80U.

Ustinov's views were not universally shared within the Soviet Army and a Defense Ministry study in 1984 concluded that for the next five-year plan, the Soviet Army could purchase 2,500 tanks and 6,000 6TD diesel engines, or 1,500 tanks and 2,000 GTD-1250 turbine engines. Ustinov's death in December 1984, followed by that of Leningrad party-boss Romanov in July 1985, removed the two most prominent supporters of the Leningrad turbine tank and cleared the way for a return to diesel tanks. Production of the T-80U at Kharkov had been painfully slow anyway, and in the event only 45 were built there. Government approval for a diesel powered T-80U was speedily granted on September 2, 1985.

The Obiekt 478 diesel program was restarted as Obiekt 478B Bereza (Birch tree) with the 6TD engine in the T-80U. A total of five prototypes were quickly completed by year's end for trials purposes, but a parallel set of prototypes based on the less elaborate Obiekt 219A with the diesel were also built for comparison. Due to the earlier studies, test and evaluation work was very quickly completed and as a result, Obiekt 478B Bereza was demonstrated at the Kharkov tank school to Mikhail Gorbachev and other senior government and army officials. Government approval for production was quickly granted in 1986 but the production program was far from trouble-free, and the Soviet Army demanded improvements before large-scale production began. The original plan had been to designate the diesel-powered T-80U as the T-84, following the Kharkov tradition of the T-34, T-44, T-54, T-64 and T-74. This proposal led to a bitter "fight under the carpet" between the industry and army, with some detractors noting that the T-84 designation would draw attention to the fact that the Soviet Army was operating four different "standard" tanks - T-64, T-72, T-80, and T-84 - all with essentially the same characteristics except for four different powerplants. The issue was so contentious that it went to the top - Gorbachev's Central Committee of the Communist Party - for a final decision. In the end, the less conspicuous designation T-80UD was selected, indicating "Improved Diesel" (Usovershenstvovanniy Dieselniy). Soviet tank production continued to decline in the late 1980s due to Gorbachev's attempts to rein in defense spending. The original 1989 plan had been for 3,739 T-80 and T-72 tanks, but this was cut back to 1,530 tanks, and the 1990 plan cut to 1,445 tanks.

Total production of the T-80UD prior to the Soviet collapse was rather modest at about 500 tanks, of which about 350 were still located at the Kharkov plant when the Soviet Union collapsed in 1991 (huom. Neuvostoliitto hajosi virallisesti 26 joulukuuta 1991 joten sinänsä oletan että tuon vuoden tuotanto valmistui kokonaisuudessaan, paitsi jos oli jotain aikataulusta myöhäisiä vaunuja sekä tuotantolinjalla tietysti keskeneräisiä eri vaiheissa kokoonpanoa). The T-80UD was first deployed with the two "Kremlin court divisions": the 4th Guards Kantemirovskaya Tank Division (4th GTD) and the 2nd Guards Taman Motor Rifle Division (MRD) in the Moscow area. The T-80UD was first publicly shown at the May 9, 1990 Victory Day parade in Red Square in Moscow. They were seen on the Moscow streets again during the attempted putsch in August 1991.

-

At the time of the Soviet collapse in 1991, the T-80 was the premium tank of the Soviet ground forces, deployed with the most combat-ready Soviet units. According to documents from the CFE Treaty, T-80 strength in November 1990 west of the Urals was 4,874. Of this strength, the vast majority was deployed against NATO, with some 3,020 T-80Bs and T-80BVs with six tank divisions and six motor rifle divisions in the GSFG and about 600 in a tank and motor rifle division in the Northern Group of Forces in Poland. A modest 705 were deployed with units in Russia, notably with the 4th GTD and 2nd Taman Guards MRD in the Moscow area, and in smaller numbers in five motor rifle divisions in the Leningrad Military District. The remaining T-80s were located in various schools, training units, and depots. Additional T-80s were located east of the Urals, such as at the Omsk plant and in depots and training schools, but these were relatively few in number. Total T-80 production was probably more than the 4,874 tanks reported under the CFE Treaty, as none were listed in the Ukraine, even though about 320 were at the Kharkov plant, and there were probably some T-80s at the Omsk tank plant as well.

As a result of the Soviet collapse, nearly all of the T-80 tanks were in Russian control except for about 350 tanks, mainly T-80UD, located in Ukraine at the Kharkov plant and less than a hundred in Belarus. The tanks stationed in German and Poland were gradually repatriated back to Russia through the mid-1990s. The collapse of the Soviet Union threw the Soviet tank industry into crisis. At the time, only three of the five assembly plants were still active. Nizhni-Tagil was manufacturing the T-72B, Kharkov was manufacturing the T-80UD, and Omsk was manufacturing the T-80U; Leningrad and Chelyabinsk were no longer very active in tank assembly. Kharkov is located in Ukraine, and so was split off from the other Soviet plants in Russia. The political turmoil was accompanied by a precipitous decline in defense funding and virtually no new tanks were funded in Russia from 1991 to about 2005, although some production continued based on existing contracts and parts.

-

Once again, the fate of the Russian tank program was determined by politics more than technology. Having been the past victim of Kremlin politics, the Uralvagon plant proved to have learned its lesson. To avoid the taint of the Chechen war, the new T-72BU version of the T-72 tank was renamed the "T-90." Eduard Rossel, the governor of the Sverdlovsk region where the Nizhni-Tagil plant was located, vigorously campaigned for the T-90 as the future Russian tank. In 1996, the Russian Army announced that the T-90 would be the preferred tank for the immediate future. The decision made little difference in the short run, as there was no procurement funding for either the T-80U or T-90 for almost a decade. In the event, the T-90 prospered, as the Uralvagon plant at Nizhni-Tagil had an extensive commercial business in railroad equipment that kept the factory alive until state orders for tanks resumed in 2005. In addition, Nizhni-Tagil had better success in the export market, winning some large T-72 and T-90 sales to India and several other countries. In contrast, Omsk had a very difficult time winning export orders. The T-80U was significantly more expensive to purchase and operate than the T-72, and the Russian Army decision in favor of the T-90 did not help the T-80's export prospects. In addition, it faced competition from the Ukrainian Kharkov tank plant, which was offering the T-80UD/T-84 on the export market. Whether the T-90 was favored or not, by the late 1990s the T-80 was the backbone of Russian tank forces. Older tanks had been retired due to a lack of funds and of the 5,546 tanks still in service west of the Urals in 1997, 3,210 were T-80 tanks, almost 60 percent.

-

A handful of export orders for the T-80U did materialize, though they were fulfilled mostly by using undelivered inventory from the Omsk plant. Morocco acquired about five T-80 tanks in the late 1980s, ostensibly for testing for a future tank requirement; it is widely believed that they ended up in the hands of US, British, and German intelligence agencies. Russia sold Britain one T-80U in 1992 as a goodwill gesture connected with President Boris Yeltsin's visit to Britain in 1992. Sweden evaluated the T-80U for its tank competition starting in 1993, but finally settled on the Leopard 2. The Russian government owed South Korea a substantial amount of money from the Soviet period, and partly paid these debts through the sale of military equipment. The Republic of Korea Army received about 80 T-80U tanks from 1996 to 2005. These are used primarily by "opposing forces" units for training. Cyprus acquired 41 T-80U tanks, including 14 of the new T-80UK command tanks in 1996-97.

Omsk attempted to reinvigorate international interest in the T-80 by more elaborate improvements, including active protection systems as detailed below. Export sales were too small to keep the Omsk tank plant busy, and in spite of a few small state orders for tank rebuilding, the plant went bankrupt in 2006. At the time of writing (huom. kirja julkaistu 17.2.2009 joten "kirjoitushetki" on jotain tuota ennen, ehkä vuoden 2008 loppu), the Russian government planned to consolidate the tank business around Uralvagon in Nizhni-Tagil, with Omsk assigned tank rebuilding efforts as well as some design work. The Russian Army began to fund upgrades for its aging T-80 fleet in the 2007 defense budget.

-

The Kharkov plant in newly independent Ukraine attempted to keep T-80 production alive there, but suffered from some unique problems. About 70 percent of the T-80UD came from plants outside Ukraine, mainly Russia. Production was 800 combat vehicles in 1991, but only 43 in 1992 and none in 1993 as the supply of components dried up. Since the Ukrainian state budget was too small to support any extensive production, the plant turned to the export market. In 1993, the Malyshev plant demonstrated the T-80UD to Pakistan and in the summer of 1995, two T-80UD underwent extensive testing there. In August 1996, Pakistan announced plans to purchase 320 T-80UD tanks from Ukraine. One critical component was the cast turret - this came from the Azvostal foundry in Mariupol, which had already ceased production; the other casting facility was at the Omsk plant in Russia. So the Malyshev plant's design bureau developed a new welded turret that resulted in the Obiekt 478BK (BK = Bereza-Katanaya: Rolled-armor birch tree), with the first completed in 1993. Ukraine began manufacturing its own version of the D-81 125mm gun at the KBA-3. Of the 320 tanks delivered to Pakistan in 1997-1999, 145 used the original cast turret, including 52 tanks completed under Soviet contracts but never delivered, plus new tanks built with remaining Soviet-era turrets, and some tanks from Ukrainian army stocks. Ukrainian Army T-80 strength fell from about 350 tanks prior to the sale to 271 afterwards. The remaining 175 tanks were the new production Obiekt 478BE with the welded turret.

-

Although the Ukrainian government made repeated promises to begin purchasing the T-84 tank for the Ukrainian Army, the budget was too small to do so. A total of ten T-84M were ordered and delivered in 2002-2003. However, the government had problems paying for all the tanks, and four were sold off to the United States in 2003. A lack of orders from the Ukrainian government or from export clients left the Kharkov plant in grave economic straits and restricted their development efforts after 2005.

-

Tämä lainaus on Zalogan kirjasta "T-90 standard tank: the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivuilta 4-6 ja tarjoaa lisätietoa panssarivaunujen tuotantomäärille 90-luvun alussa:

-

The imposition of the “defense sufficiency” doctrine in the Gorbachev years led to substantial reductions in Soviet tank production. The Soviet Union had five tank plants in 1980 but only three remained active by 1991. After the Soviet collapse, only two remained inside the Russian Federation. Annual tank production plummeted from 3,254 in 1987 to 1,000 in 1991 and fell rapidly after that. The Kharkov tank plant, long considered the premier Soviet tank design and production center, had produced 800 T-80UD tanks in 1991. Since it was located in Ukraine, the Kharkov plant was cut off from the Russian Federation. T-80U production in St Petersburg at the Leningrad Kirov Plant ceased in 1990 prior to the Soviet collapse. T-72 production at the Chelyabinsk Tractor Plant (ChTZ) had ceased in 1989 after 1,522 had been built there. This left only two functioning tank plants in Russia, the Uralvagonzavod (UVZ: Ural Rail-Car Plant) in Nizhni-Tagil and the Transmash plant in Omsk in Siberia. Of these two, the UVZ in Nizhni-Tagil was the more significant. It included both a substantial design bureau, nicknamed the “Vagonka,” as well as a large manufacturing facility. It had been responsible for the design of several Soviet tanks during the Cold War years including the T-55, T-62 and T-72. The Omsk plant had a very small design staff and was regarded as a subsidiary plant, usually manufacturing tanks developed at other locations. At the time of the Soviet collapse, the T-80U was still in production at the Transmash Plant in Omsk while T-72 was in production at UVZ in Nizhni-Tagil.

In 1992, the Russian defense ministry made it clear that it could no longer afford to simultaneously buy two main battle tanks. Russian officials stated that they wished to cut production down to a single type, either the T-72 or the T-80. However, selecting one or the other tank meant that economic catastrophe would befall the losing city. Therefore, Russian officials continued to order both types in small amounts. In 1992, the Russian Army ordered only 20 tanks: 5 T-80U tanks from Omsk and 15 tanks from Nizhni-Tagil. Tank production at Omsk and Nizhni-Tagil in 1992–93 was well beyond the puny state orders due to some export orders, but only a pale shadow of the 1980s. This additional production was not ordered by the Russian Army, but undertaken simply to keep the plants from closing. There was the hope that large export orders would emerge to save the plants and sop up this surplus. However the anticipated export orders did not materialize. The UVZ in Nizhni-Tagil had about 350 T-72S and T-90 tanks in its factory yards, and Omsk had 150−200 T-80U tanks. Some of these T-80U tanks were exported to Cyprus and South Korea in 1996; UVZ gradually exported the T-72 tanks. Lack of pay at the Nizhni-Tagil plant led to strikes in July 1995 during which the workers seized several of the idle tanks and drove them through the city in protest.

-

Taulukko Steve Zalogan kirjasta "T-80 standard tank - Soviet armys last champion" (kirja julkaistu 17.2.2009) sivulta 34:

Tämä taulukko on Zalogan kirjasta "T-90 standard tank - the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivulta 10. Huomaa, että vuoden 1991 numerot koskevat Neuvostoliittoa, mutta 1992 on pelkästään Venäjä. Siitä puuttuu siis Ukrainan ja Valko-Venäjän omistukseen siirtyneet vaunut, ehkä myös osa on siirretty Uralin itäpuolelle:

Tässä ovat T-80 vuosittaiset valmistusmäärät kuten ne on kerrottu siinä Nizhny Tagilin taulukossa (johon Zaloga viittaa omassa taulukossaan kirjassa "T-90 standard tank: the first tank of the new Russia" (kirja julkaistu 20.2.2018) sivulla 5):

Zalogan kirjoittaman perusteella jako vaunutyypeittäin:

Viimeksi muokattu:

Antares

Respected Leader

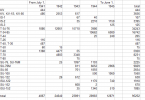

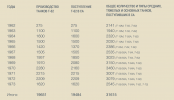

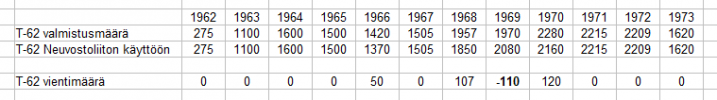

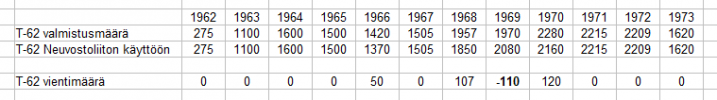

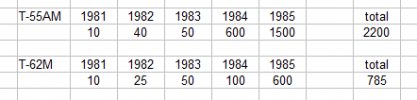

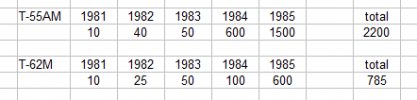

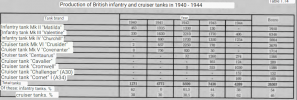

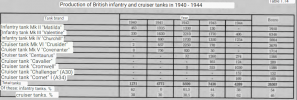

T-62 vaunujen valmistusmääristä sekä vientimääristä.

Alla olevan taulukon lähde:

Уральский вагоностроительный завод. 80 лет - С. В. Устьянцев - 2016

Ural Carriage Works: 80 years - Ustyantsev S. V. - 2016

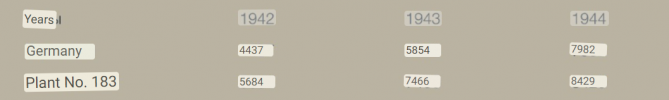

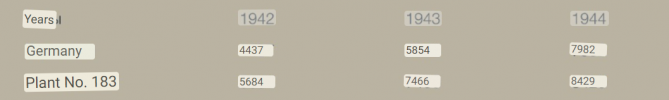

Sivulta 75

Kuten kirjan nimestä nähdään, se käsittelee Uralvagonzavodia. Siellä kirjoitetaan että kukaan muu ei valmistanut T-62 vaunuja, joten ylläoleva on heidän tuotantomääränsä per vuosi - ja samalla koko T-62 tuotanto Neuvostoliitossa.

Kun vertaa tätä taulukkoa tästä ketjusta löytyvään Solyankin et. al. vuosia 1946-1965 käsittelevästä kirjasta otettuun taulukkoon niin havaitaan että numerot täsmäävät kokonaismäärien kanssa, mutta tässä taulukossa on laskettu kaikki T-62 mallit yhteen. Täten esim. T-62 ja T-62K ei ole eritelty. Taulukkoja vertaamalla nähdään:

1963 - 1 069 kpl T-62 + 31 kpl T-62K = 1 100

1964 - 1 521 kpl T-62 + 79 kpl T-62K = 1 600

1965 - 1 450 kpl T-62 + 50 kpl T-62K = 1 500

Harmillisesti Solyankin et. al. taulukko päättyy vuoteen 1965, joten tämän jälkeen on pelkästään yllä olevan taulukon kokonaismäärät ilman tarkempaa jaottelua malleihin. Toki se on parempi kuin ei mitään.

Tuossa yllä olevassa T-62 vaunuja käsittelevässä taulukossa on kolme saraketta:

1) näistä ensimmäinen vasemmalta kertoo T-62 vuotuiset valmistusmäärät (Uralvagonzavod oli ainoa tehdas joka valmisti T-62 vaunuja),

2) tuosta seuraava sarake oikealle on Neuvostoliiton käyttöön tulleiden T-62 vaunujen määrä ja

3) siitä seuraava oikealle on kyseisenä vuonna Neuvostoliiton käyttöön tulleiden "medium, heavy and main battle tanks" määrä - eli kertoo määrän sekä luovutettujen vaunujen tyypin ilman tarkempaa jakoa. Listassa mainitaan vaunutyypit T-10M, T-55, T-55A, T-55/55A, T-62, T-64, T-64A ja ihan viimeisellä rivillä T-72.

Täten T-62 vaunujen ulkomaanviennin saa laskettua kun vähentää sarakkeen 1 numeroista sarakkeen 2 numeron. Tuosta voidaan siis laskea näin:

Vuoden 1969 kohdalla Neuvostoliiton käyttöön olisi tullut suurempi määrä vaunuja kuin mitä on valmistettu. Oletan että tuossa on lipsahtanut numerot väärille sarakkeille, pitäisi olla toisinpäin.

Jos oletetaan tuo virheeksi, niin T-62 viennin kokonaismääräksi saataisiin 387 vaunua, mutta tämän tiedetään olevan liian pieni määrä. Olen aina tulkinnut tätä siten että tuo määrä oli uustuotannon vientiä ja kaikki muu oli Neuvostoliiton omista varastoista tehtyä vientiä sitä mukaa kun saivat T-64A, T-64B, T-72 ja T-80 vaunuja lisää riviin. Uralvagonzavod aloitti T-72 valmistuksen vuonna 1973 joten T-62 tuotanto päättyi samalla.

Seuraava lainaus koskee T-62 vientiä.

Lähde:

T-62 main battle tank 1965-2005 - Steve Zaloga - 18.8.2009

Kirjan sivuilta 30 ja 31:

EXPORT BONANZA

Unlike the T-54 and T-55, the T-62 was never license manufactured outside the Soviet Union. Polish and Czech sources suggest that the reasons were in part due to cost. The sale price of the T-62 was R250,000, which was about 50 per cent greater than the cost of the T-55 at the time. Furthermore, senior Warsaw Pact officials were aware that the Soviet Army was adopting the new T-64A as their "universal tank," so a short-term transition to the T-62 hardly seemed worth the effort. The Soviet invasion of Czechoslovakia in August 1968 also delayed modernization of the Martin tank plant, and political turmoil and economic liberalization in Poland also put a cap on defense modernization there. US intelligence believed that Czechoslovakia manufactured about 1,500 T-62 tanks, but this appears to have been a mistake judging from recent Czech and Slovak accounts. The only Warsaw Pact army to adopt the T-62 was Bulgaria, which acquired about 80, selling these off in 1993-94 to Angola and Yemen. There have been reports that North Korea has manufactured copies of the T-62 as the Chonma tank, but it is not clear whether this is true or whether they are locally improved versions of Soviet manufactured tanks. Although the T-62 never played a major role in Warsaw Pact modernization, it became a trademark of the expanding Soviet arms trade in the 1970s, especially in the Middle East and Africa. Of the more than 19,000 T-62 tanks manufactured, over 5,000 were exported in the 1970s and 1980s and more in later years. The figures below are from a variety of sources and many are estimates, as no official data has been released.

Sales of new tanks largely ended by the early 1980s, but the collapse of the Soviet Union in 1991 led to a second wave of sales as former Soviet republics such as Belarus and Ukraine dumped their older tanks on the market. As a result, T-62s have shown up in additional locations beyond the formal sales programs detailed above, with more recent sales to Sudan, the Congo, and other hot spots.

-

Tuon taulukon numeroiden summa on 4 960, toki kuten hän kirjoittaa, osa näistä on parempia ja varmempia kuin toiset: virallisia vientinumeroita ei ole tiedossa, ainoastaan tällaista eri lähteistä parsittua dataa. Toki pitää muistaa että hänen kirja on julkaistu 18.8.2009, joten sen jälkeen on voitu saada parempaa tietoa. Sama taulukko mutta aikajärjestyksessä:

HUOM: Olen nähnyt kirjoituksia, joiden mukaan T-62 kokonaistuotanto olisi hieman yli 22 700 vaunua, joista noin 20 000 olisi valmistettu Nizhny Tagilissa (1961-1973) ja loput Omskissa (1961-1975) - tosin Omskin osalta määrät ja aikavälit eivät ole selviä. Ustyantsev S. V kirjassa "Уральский вагоностроительный завод. 80 лет" joka on eräänlainen Uralvagonzavodin virallinen historiikki, kirjoitetaan että he olivat ainoa tehdas joka valmisti T-62 vaunuja (tuo yllä oleva taulukko on otettu ko. kirjasta). Olen aina olettanut tämän pitävän paikkansa, mutta paras silti mainita että internetissä näkee myös väitteitä, joiden mukaan Omsk olisi valmistanut T-62 vaunuja.

Omsk valmisti valtaosan T-55 vaunuista, usein näkee numeroa 13 032 ja kokonaismäärän ollessa jotain 20 000 tienoilla. Aikaväli mahdollisesti 1958-1979. Erityisesti tuotannon häntäpäästä valtaosa meni vientiin. Kharkovan tehdas valmisti T-55 vaunuja lyhyen aikaa 1959-1963 ennen kuin aloittivat Obyekt 432 eli alkuperäisen T-64 tuotannon. Nizhny Tagil valmisti loput T-55 määrästä, tosin heidän T-62 tuotanto alkoi 1961 ja oletan että korvasi kokonaan T-55 tuotannon tuon vuoden jälkeen. Neuvostoliiton ulkopuolisissa maissa valmistettiin (väitetysti) seuraavat määrät T-55 vaunuja seuraavina aikaväleinä (Puolan ja Tsekkoslovakian vaunuista osa meni vientiin):

- Bumar-Labedy tehdas Puolan Gliwicessä - 1 500 vaunua (1964-1978),

- Tsekkoslovakian ZTS (Zavod Trucanske Strojarne) tehdas sijaitsee Martin-nimisessä kaupungissa (nykyään Slovakia alueella) - 1 700 vaunua (1964-1973)

- Romanian Bucharestissa sijaitseva Fabrica de Mașini Grele Speciale - 400 vaunua (1979-1985).

Omskin T-55 vaunujen tuotanto jatkui Nizhny Tagilin T-62 vaunuja pidempään koska T-72 Uralin tuotannon alkaminen vuonna 1973 korvasi T-62 tuotannon. Käytännössä Omskin T-55 tuotanto jatkui T-80 vaunujen valmistuksen alkuun eli vuoteen 1979 asti. On tietysti mahdollista että he olisivat pystyttäneet hetkeksi T-62 tuotantolinjan, jolla olisi valmistettu tuo huhuttu hieman yli 2 270 vaunua. Teoriassa olisi myös mahdollista että Omsk olisi tehnyt pelkästään kokoonpanoa Nizhny Tagilin toimittamien kittien osalta, mutta hieman epäilyttää tämäkin: Uralvagonzavod on helvetin iso tehdas, heillä tuskin olisi ongelmia kokoonpanon osalta. Omsk puolestaan oli kiireinen T-55 vaunujen kanssa, ei käy järkeen että sitä mentäisiin sotkemaan "pienellä erällä vieraita vaunuja". Hyvä myös muistaa että suuresta valmistusmäärästä huolimatta T-62 vaunua pidettiin jopa Varsovan liiton sisällä kalliina ja väliaikaisena ratkaisuna, kaikki tiesivät jo 60-luvulla että parempaa oli tiedossa T-64 vaunujen muodossa ja kun niitä ei tarjottu vientiin, niin T-72 oli seuraava vaihtoehto 1973 jälkeen (tosin vienti alkoi myöhemmin). T-55 vientikauppa kävi hyvin sen halvan hinnan, helpon käytettävyyden sekä vaunun hyvän kestokyvyn takia.

Ehkä jossain vaiheessa törmään tiedonmuruseen joka selventää asian, mutta toistaiseksi olen nojannut pelkästään Nizhny Tagilin taulukkoon ja pitänyt sitä virallisena totuutena valmistusmäärien osalta. Olen myös pitänyt selvänä että Nizhny Tagil oli ainoa tehdas joka valmisti T-62 vaunuja, tosin joskus muisti pettää ja saatan toistaa vahingossa tuota juoruilua Omskin T-62 tuotannosta.

-

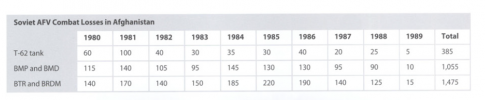

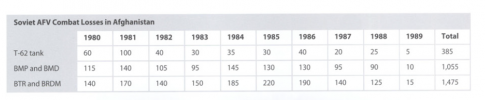

Pari knoppitietoa T-62 osalta, koskien vaunujen menetyksiä Afganistanin sodassa 1979-1989.

Lähde:

T-62 main battle tank 1965-2005 - Steve Zaloga - 18.8.2009

Teksti kirjan sivuilta 39 ja 40, taulukko on sivulta 42:

The T-62 also saw its first extensive use in Soviet hands during the savage conflict in Afghanistan in 1979-1988. The Afghan Army had been partly equipped with T-62 tanks in the early 1970s prior to the eruption of the civil war. The Communist coups in Afghanistan in 1978-1979 and the continued disintegration of government control prompted a Soviet intervention that began on December 24, 1979. The main Soviet Ground Force element sent into Afghanistan was the Fortieth Army, and since it was located in areas far removed from the main confrontation zones facing NATO, its equipment was

older.

The predominant tank type was the T-62, since there was little point in deploying more modern types such as the T-64 or T-72 when the opposition was a guerrilla force without tanks. Some Soviet T-62 tanks were dug in and used to form the core of firebases; others were employed for patrols and convoy protection, and others were used for infantry support during the Soviet attacks on mujahedeen positions. RPG-7 anti-tank rockets and mines were the main threats to the T-62.

The T-62M upgrade program was partly a response to these threats, with the anti-mine package being largely motivated by the Afghan experience. In Afghanistan, the uparmored T-62M1 was locally called T-62D (dopolitelnoy zashchita: extra protection). By 1987, the Soviet tank force in Afghanistan included 625 T-62 tanks. Total tank combat losses in Afghanistan from 1980 to 1989 was around 385, almost all T-62s. However, 1,340 T-62 tanks were written off by Soviet units in Afghanistan, which includes combat losses, worn-out tanks, and tanks not worth recovering.

Alla olevan taulukon lähde:

Уральский вагоностроительный завод. 80 лет - С. В. Устьянцев - 2016

Ural Carriage Works: 80 years - Ustyantsev S. V. - 2016

Sivulta 75