Ilmeisesti BTR-90:ssä oli myös vaihtoehtoinen liukuohjaus.

The increase of the hull size, of course, led to an increase in mass, and immediately the question arose about the presence, or rather, the absence of a suitable engine. According to calculations, a 450–500 hp diesel unit was required, and there were only two of them: the Barnaul UTD-29, mass-produced for the BMP-3, and the Chelyabinsk 2V-06 for BMD-3 family vehicles. Both engines had their advantages and disadvantages, but no “extra" UTD-29 was expected, since in those years the plans for the production of BMP-3 were truly grandiose.

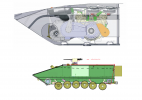

The choice fell on the 2V-06-2M with power of 510 hp. It was a six-cylinder, four-stroke, multi-fuel liquid-cooled diesel engine with an opposed cylinder arrangement, direct fuel injection, gas turbine supercharging and intermediate intake air cooling. The machine used a hydromechanical transmission, which was quite unusual for wheeled vehicles, with a differential-type hydraulic volumetric rotation mechanism. The gear and turning mechanism worked in such a way that it was single-threaded with straight movement and double-threaded during vehicle turns. Power flows were distributed on the sides; this design was used before in special wheeled chassis of the SKSh135 family of development by V.A. Gracheva and serially not used anywhere else.

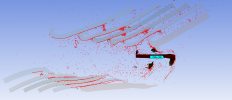

Thanks to the use of this transmission scheme, it was possible to improve the controllability and maneuverability of the armored personnel carrier. On soft soils, it could turn around "like a tank", asimilar to neutral steering. On roads, an APC could move without decreasing speed in turns, since by what amount the output shaft speed of the outgoing side increased, the output shaft rotation frequency decreased by the same amount. The hydromechanical gearbox was reversible, which allowed the armored personnel carrier to move at the same speeds both forward and backward. This also greatly increased the maneuverability of the vehicle. The selection of power to the water jets and the hydraulic control pump for the transmission was carried out regardless of the choice of gear.

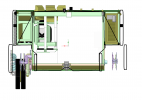

The power was provided by a 950B power unit with a 2V-06-2M engine, a gear and rotation mechanism with an automatic gearbox AU9 - as well as an engine borrowed from the BMD-3, two transfer gearboxes, eight final drives and eight wheel gearboxes. The use of wheel reducers allowed to increase the clearance of the armored personnel carrier to 500-510 mm. The independent suspension was structurally similar to the BTR-80 suspension. Each wheel was suspended on two A-shaped wishbones. As elastic elements, longitudinal torsions were used. In the suspensions of the first and fourth pairs of wheels, two telescopic hydraulic shock absorbers were installed per wheel, in the others - one per wheel.

Disk wheels, with a split rim and OI-25 tires of dimension 14R20, borrowed from the Ural-4320 truck. They had a system for regulating tire pressure and allowed to continue driving in the absence of excessive tire pressure. The steering with hydraulic booster worked on the wheels of the first and second axles.

sturgeonshouse.ipbhost.com

sturgeonshouse.ipbhost.com

The increase of the hull size, of course, led to an increase in mass, and immediately the question arose about the presence, or rather, the absence of a suitable engine. According to calculations, a 450–500 hp diesel unit was required, and there were only two of them: the Barnaul UTD-29, mass-produced for the BMP-3, and the Chelyabinsk 2V-06 for BMD-3 family vehicles. Both engines had their advantages and disadvantages, but no “extra" UTD-29 was expected, since in those years the plans for the production of BMP-3 were truly grandiose.

The choice fell on the 2V-06-2M with power of 510 hp. It was a six-cylinder, four-stroke, multi-fuel liquid-cooled diesel engine with an opposed cylinder arrangement, direct fuel injection, gas turbine supercharging and intermediate intake air cooling. The machine used a hydromechanical transmission, which was quite unusual for wheeled vehicles, with a differential-type hydraulic volumetric rotation mechanism. The gear and turning mechanism worked in such a way that it was single-threaded with straight movement and double-threaded during vehicle turns. Power flows were distributed on the sides; this design was used before in special wheeled chassis of the SKSh135 family of development by V.A. Gracheva and serially not used anywhere else.

Thanks to the use of this transmission scheme, it was possible to improve the controllability and maneuverability of the armored personnel carrier. On soft soils, it could turn around "like a tank", asimilar to neutral steering. On roads, an APC could move without decreasing speed in turns, since by what amount the output shaft speed of the outgoing side increased, the output shaft rotation frequency decreased by the same amount. The hydromechanical gearbox was reversible, which allowed the armored personnel carrier to move at the same speeds both forward and backward. This also greatly increased the maneuverability of the vehicle. The selection of power to the water jets and the hydraulic control pump for the transmission was carried out regardless of the choice of gear.

The power was provided by a 950B power unit with a 2V-06-2M engine, a gear and rotation mechanism with an automatic gearbox AU9 - as well as an engine borrowed from the BMD-3, two transfer gearboxes, eight final drives and eight wheel gearboxes. The use of wheel reducers allowed to increase the clearance of the armored personnel carrier to 500-510 mm. The independent suspension was structurally similar to the BTR-80 suspension. Each wheel was suspended on two A-shaped wishbones. As elastic elements, longitudinal torsions were used. In the suspensions of the first and fourth pairs of wheels, two telescopic hydraulic shock absorbers were installed per wheel, in the others - one per wheel.

Disk wheels, with a split rim and OI-25 tires of dimension 14R20, borrowed from the Ural-4320 truck. They had a system for regulating tire pressure and allowed to continue driving in the absence of excessive tire pressure. The steering with hydraulic booster worked on the wheels of the first and second axles.